|

Home » Sponsored » Pi Speakers » Modifed 4 Pi Build Report (Design)

| Modifed 4 Pi Build Report [message #68569] |

Fri, 15 July 2011 23:46  |

Dave_S

Dave_S

Messages: 28

Registered: April 2011

|

Chancellor |

|

|

This my build thread of modified 4 Pi speakers. I purchased the parts from Wayne and chose the B&C DE250 compression driver upgrade, the JBL 2226 woofer upgrade, the 15 gauge inductor upgrade, the Jantzen Zcaps upgrade, and the Mills resistor upgrade.

What drew me to the 4 Pi speakers was that I had only heard one pair of commercial speakers that impressed me. Those were the Klipsch Chorus II speakers. At that time, I turned of the clasical music that sounded good on most speakers to my untrained ear and put my own CD of various alternative rock music. All speakers failed to impress, except the Klipsch. Since I did not have the money at that time after college, I selected the Polk 5 Jr+ speakers. Nowadays, Klipsch are not even available to listen to in my area. Over the years, I have listened to other speakers and determined that it was not worth the money to upgrade from my Polk 5 Jr+ speakers. I was left unimpressed and had almost given up upgrading my speakers. I do not have access to stores that have high end speakers, except the Best Buy Magnolia Room that has speakers that cost up to $1000 a piece. All of those speakers sound really bad to me and left me wondering if my hearing had degraded to the point where no speaker would sound decent. While on a trip, a coworker convinced me to consider building speakers. My only experience building speakers was in college. I randomly changed out drivers from old speakers with new drivers purchased from Radioshack. I made cross overs from windings made of magnet wire. They failed to impressed and I would never have considered building my speakers myself had it not been for the coworker.

Klipsch Chorus II speakers:

It was sort of shot in the dark, but I decided on 4 Pi speakers. To me it was a huge risk. One reason was that I decided to take the risk was that the speakers had a similar look to the Klispch speakers that I liked. I had never taken the grills of of the Klipsch speakers and the term horns meant nothing to me at the time. The Pi speakers also have more positive reviews than any other DIY speaker that I could find; the one exception might be the Linkwitz Lab Orions, but I did not have enough money burning a hole in my pocket. In many forums, Pi speakers are not mentioned and other designers are mentioned as having a good speaker design "pedigree". However, it was usually difficult to find people that had built the speakers. As for 4 Pi speakers, there were the build reports like I am doing that were all favorable. However, if you look at places like newegg.com, most all reviews of speakers that would make me cringe are positive. I placed more weight on forum posts where people were asked if they had heard the Pi speakers. There was often the reply that the person had walked by them while being demoed and they sounded really good. They were people with nothing invested in having anything but an honest oppinion.

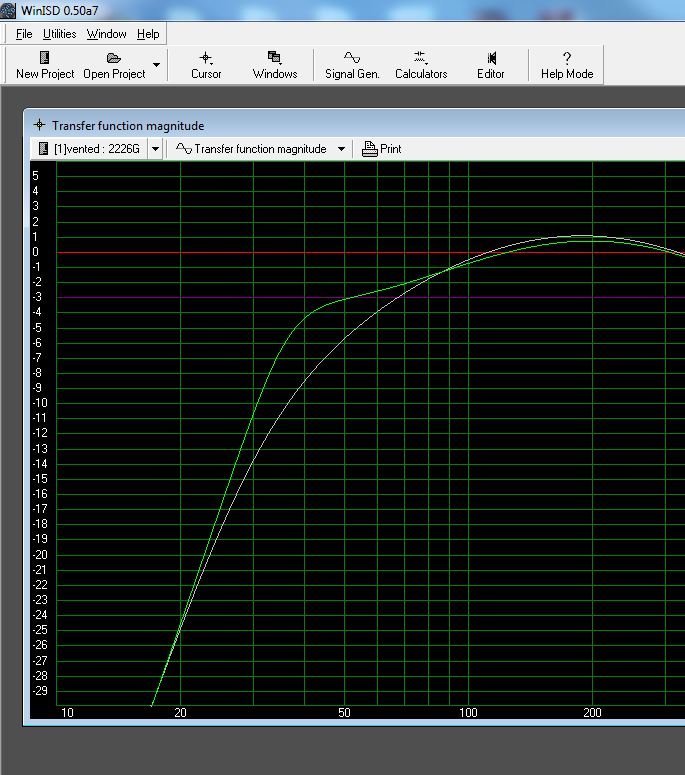

Looking at the frequency response, my coworker was surprised by the frequency rolloff at the low end of the speaker. He concluded it was probably due to cabinet size. After some research, I determined that it was and decided to research making a larger enclosure. During the research, I saw that Wayne liked the rolloff of the 4 Pi design, because it blends with the subwoofers well. Since I may (at least initially) skip the subwoofers, I decided to make larger enclosures to extend the low frenquency response. It was a major decision because of the size. I decided on an enclosure that is about 5 cubic feet in volume. It could have been easily decreased down to 4.5 cubic feet with little negative affect, but due to other design issues, I ended up with my final enclosure size. For determining the enclosure size and frequency response, I used WinISD. I kept the enclosure tune to 38 Hz like the original 4 Pi design. The software is easy to use, but it does not shut down properly in Windows 7. I had to do a control-alt-delete to kill the program. The theoretical frenquency response of my speaker compared to the stock 4 Pi is shown below. The modified 4 Pi is the green curve:

The software does not have any ability to determine standing wave issues to to the modified enclosure design. I had to take the risk. In addition, the tweeter/crossover cannot be included in the design.

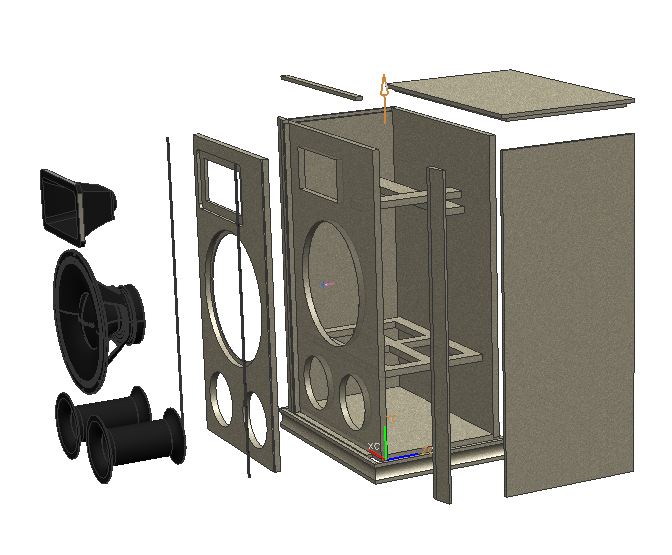

For the design, I used Unigrahics for the cabinet design. It is the software that I use most days at work. I decided on base and wood trim to protect some of the veneer edges and provided a contoured edge. This is the design that I came up with:

The following image is a comparison of the 4 Pi speaker to the modified 4 Pi speaker:

|

|

|

|

| Re: Modifed 4 Pi Build Report [message #68570 is a reply to message #68569] |

Fri, 15 July 2011 23:56   |

Dave_S

Dave_S

Messages: 28

Registered: April 2011

|

Chancellor |

|

|

Here are a few images of the build. I chose baltic birch for the sides and a cherry veneer.

Router guide for horn:

Rear open encolsure:

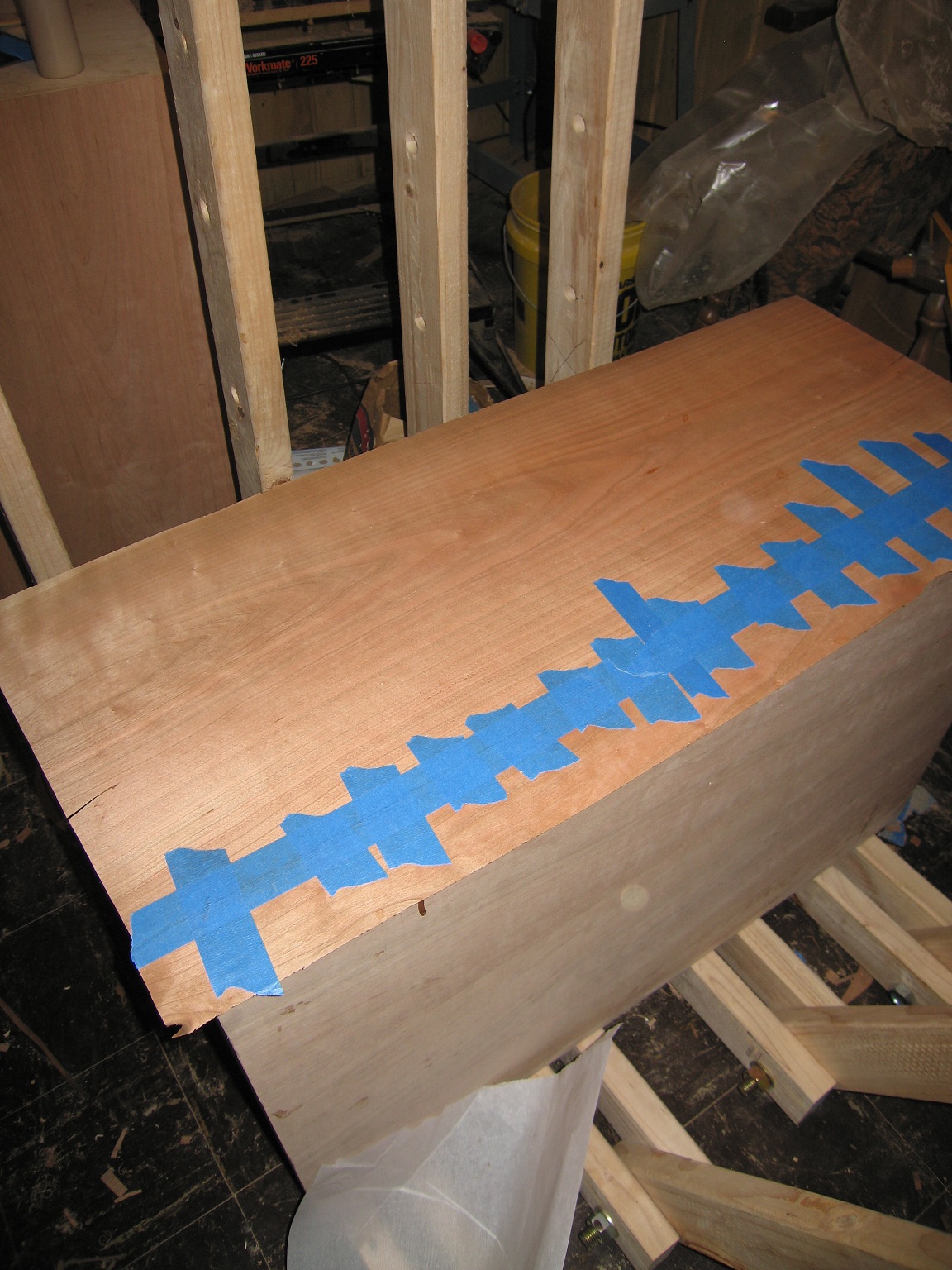

I decided to use spliced leaves of veneer and made a what was probably a bad choice of contact cement to apply the veneer. Following the glue directions closer might have helped, but I had done some veneer work years ago and had decent results. I thought that I knew what I was doing. That wasn't the case. I started on the backs of the speakers, but the results were so bad that I stripped the veneer off and decided to start over. To replace the veneer, I purchased 2-ply veneer and it worked well. There was a lot more stiffness, structure, and durability than the veneer leaves that I was using. Looking back, changing the brand of contact cement may have worked with 2-ply veneer, but I decided to make a veneer press. Some of the veneer press images are shown below:

The press works fairly well. I am sure that it doesn't come neer the 100 psi recommended on the bottle, but vacuum presses can't exceed 14.7 psi, so I took the chance. In general the press worked well. In the future, I would expand my press clamps from 8 to 12. My first attempt to span about 3.5 ft with 2X4s. I used 4 press clamps on the first assembly. A 2X4 broke with force being applied by any of the clamps. I switched to 2X6 lumber on the top and increased the strength by a factor of about 2.5 times. I also used fewer clamps per assembly and shorted the span of each assembly to about 2 feet. This increased the press strength substantially. I was still never sure if anything would break but it worked well. For the platten that was used to press the veneer, I glued and nailed two sheets of plywood to make a stifff platten. For places where I rounded the corners of the cabinet with my sander, I had to go back and reclamp those area separately. I also ran into problems on the front of the speaker cabinets. The area between horn and the woofer were too flexible to generate a decent clamping force. If my internal braces were in place, it probably would have worked better. I definitely do not recommend that everyone switches from veneering to building a press. The press was expensive and still had areas where the veneer did not adheer properly. If people use a better contact cement and a more rigid veneer like 2-ply or NBL veneer, they should be fine. Also, I don't think that a veneer press would be a suitable choice for MDF due to strength and flexibility issues. Next time, I will probably take Bill Epstein's advice and try urea resin for glue.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Goto Forum:

Current Time: Sat Feb 07 07:02:45 CST 2026

|