|

Home » Sponsored » Pi Speakers » 12π basshorn subwoofer - the best yet!

| 12π basshorn subwoofer - the best yet! [message #51447] |

Thu, 04 October 2007 14:33  |

|

Wayne Parham

Wayne Parham

Messages: 19000

Registered: January 2001

|

Illuminati (33rd Degree) |

|

|

I designed the 12π basshorn subwoofer as a signature statement product, the best high-fidelity and the highest SPL from 30Hz to 100Hz. It's a no-compromise design.

- Push-pull drive reduces distortion. The second harmonic is cancelled and horn folding reduces harmonics from third up. So harmonic distortion is very low.

- The cooling plug keeps the motors cool, so there's less electro-mechanical parameter shift as power is increased. Sound quality is excellent at low, moderate and even high power levels, and the system is more robust.

- Ample mouth area and flare profile along with careful selection of front and rear chamber sizes makes the response curve smooth. Where some basshorns get peaky when used outdoors unless used in groups, the 12π basshorn response is nice and smooth.

- Maximum SPL is increased when several 12π basshorns are clustered in groups, but this is not required to smooth response. Sound quality is excellent even when just one π basshorn subwoofer is used.

All of these qualities were brought together into one design, making it the best quality subwoofer for high-fidelity and high output. It delivers in both of these areas, in my opinion, being the best subwoofer you can get for the 30Hz to 100Hz subwoofer range.

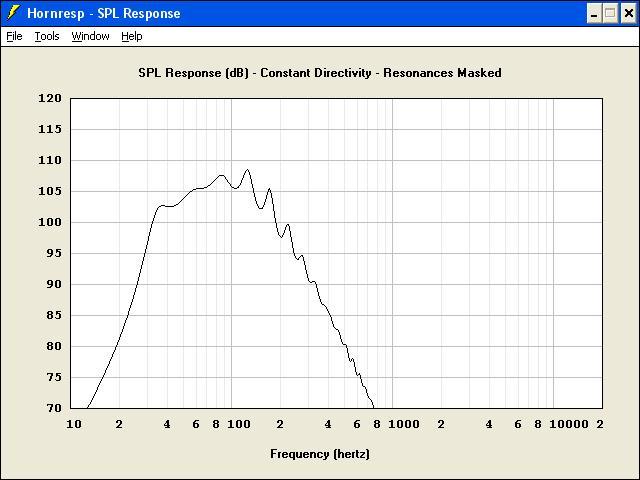

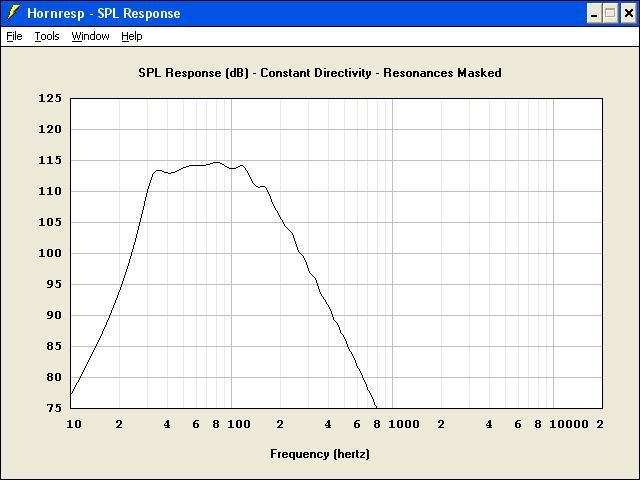

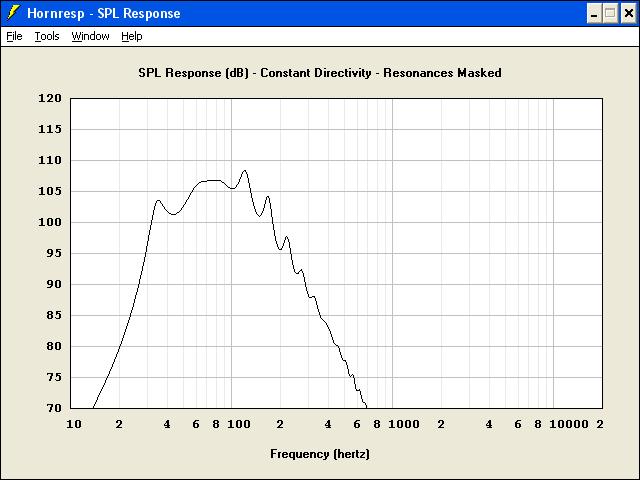

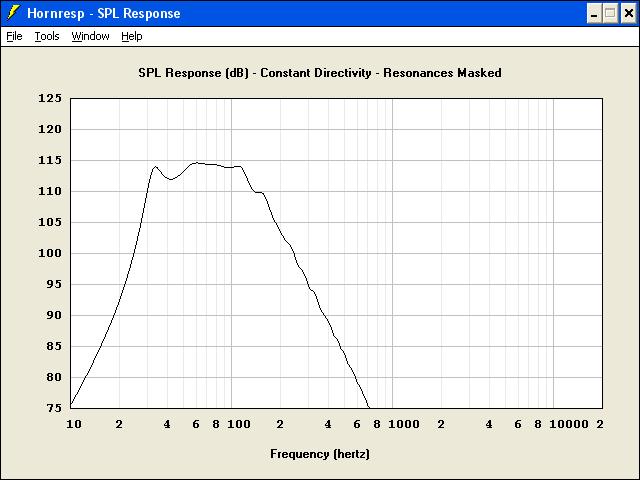

See the response curves below. The graph on the left shows response of a single 12π basshorn with 1.0 watt input signal. The graph on the right shows response of a group of horns.

12π basshorn design, single horn response

12π basshorn design, single horn response

12π basshorn design, group of four

12π basshorn design, group of four

The prototype was able to deliver all the things hoped for in the original design goals. The only thing that was difficult was front chamber size. The design called for 20 liter combined front chamber volume and 50 liter rear chambers. The magnet in one of the front chambers made it difficult to make small unless fill was used. Even then, adding enough fill to reduce chamber volume to the right size would make assembly and service difficult, so I decided to make that front chamber as small as practical, and to match the other side to it. The end result was approximately 30 liters front chamber volume.

12π basshorn prototype, single horn response

12π basshorn prototype, single horn response

12π basshorn prototype, group of four

12π basshorn prototype, group of four

Notice a slight dip around 42Hz in the prototype, due to front chamber being larger (30 liters) than the original design (20 liters). But response was still very good, and I was pleased with its performance. See the actual measurements of the prototype at the 2005 Prosound Shootout.

When we started laying out the production version of the 12π basshorn, I explained the situation to the CAD/CNC programmer. His goal was to balance ease-of-assembly and service with optimizing chamber sizes. The front chamber was to be made as small as possible, since it was physically impossible to make it too small. I allowed him some leeway, with the understanding that the flare profile should remain the same.

He was able to reduce front chamber volume to 27 liters, which was a good thing. We were both excited that he was able to do this, without making the horn hard to assemble and service. Being a production version, we were also able to count on consistency of dimensions of each part.

But there was one negative consequence that came from this process. The CAD/CNC programmer misunderstood the behavior of the rear chamber. He inadvertently reduced its size when he made the front chamber smaller. This effectively canceled the benefits of front chamber reduction, and even increased the dip at 42Hz. I didn't notice this until the production model was completed and several units were produced. The front chamber was 27 liters, but the rear chamber volume had also been reduced to 40 liters.

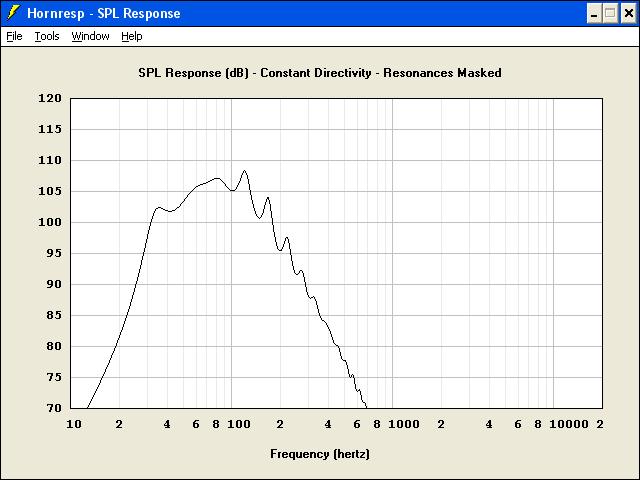

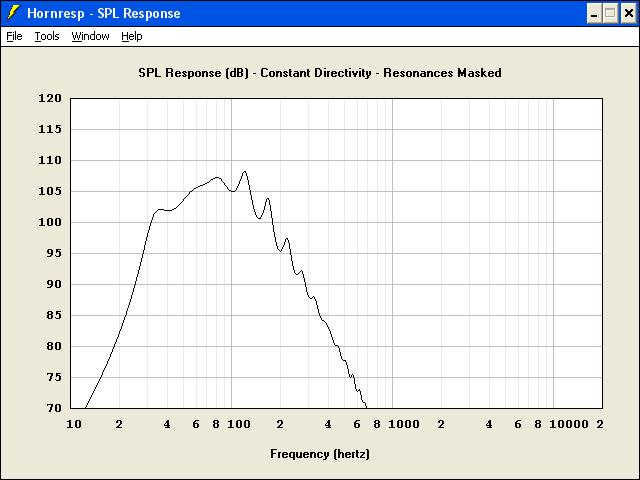

12π basshorn v1, single horn response

12π basshorn v1, single horn response

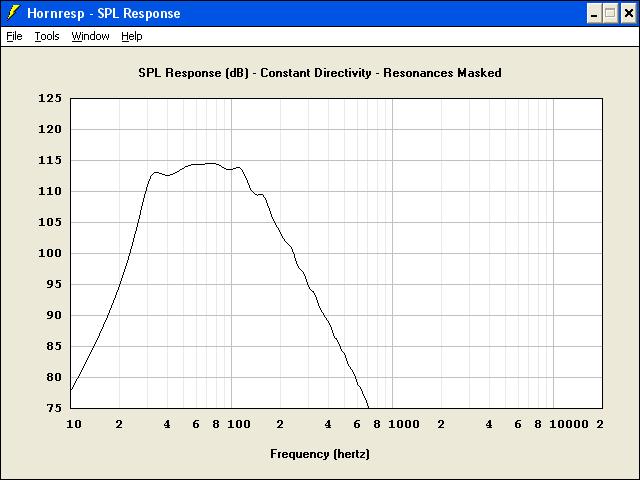

12π basshorn v1, group of four

12π basshorn v1, group of four

As you can see, the dip around 42Hz has grown in this version, due to rear chamber being smaller (40 liters) than the original design (50 liters). The dip is only about 2dB, which certainly isn't bad, especially for a basshorn. See the actual measurements of the v1 version basshorn at the 2006 Prosound Shootout. Owners of v1 version 12π basshorn subs are extremely pleased with their performance, arguably the best production basshorn subwoofer on the market. But it bothered me that this version wasn't as good as the prototype.

We have just completed a second version (v2) of the 12π basshorn subwoofer. We've learned that 27 liters is about as small as we can make the front chamber and still keep the design easy to build and service. So I decided that should be a fixed target, rather than the original design goal of 20 liters. With front chamber volume being fixed at 27 liters, I found the rear chamber volume that would make response be as flat as the original 20/50 design. What I found was that 54 liters was the optimal rear chamber volume when the front chamber was 27 liters. The motor chamber of the v2 (27/54) combination also took up the same space as the prototype (30/50), which keeps the flare profile layout spiraling around it perfectly.

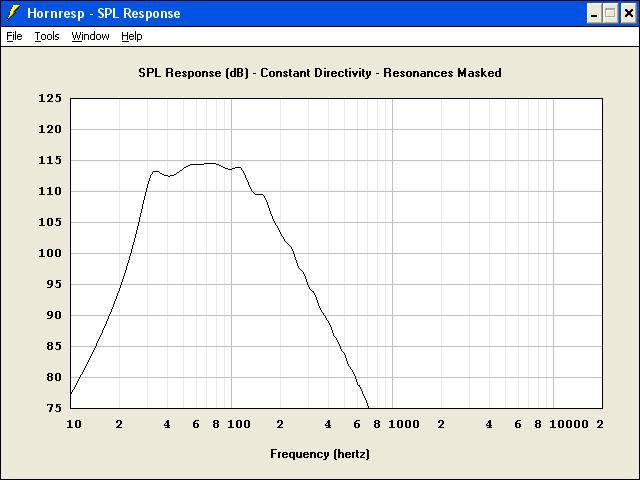

12π basshorn v2, single horn response

12π basshorn v2, single horn response

12π basshorn v2, group of four

12π basshorn v2, group of four

The 12π v2 basshorn subwoofer is a real winner, because it maintains the original design goals even better than the prototype did. It is truly a high-fidelity basshorn, with response that promises to be better than any basshorn sub I've seen. I'm very excited about it.

|

|

|

|

|

|

|

|

| Push-pull benefits quantified [message #51497 is a reply to message #51450] |

Thu, 25 October 2007 10:22   |

|

Wayne Parham

Wayne Parham

Messages: 19000

Registered: January 2001

|

Illuminati (33rd Degree) |

|

|

I've measured a handful of basshorns over the years and built a small database of measurements that show distortion at various power levels. This provides an opportunity to compare the 12π basshorn subwoofer with other basshorns.

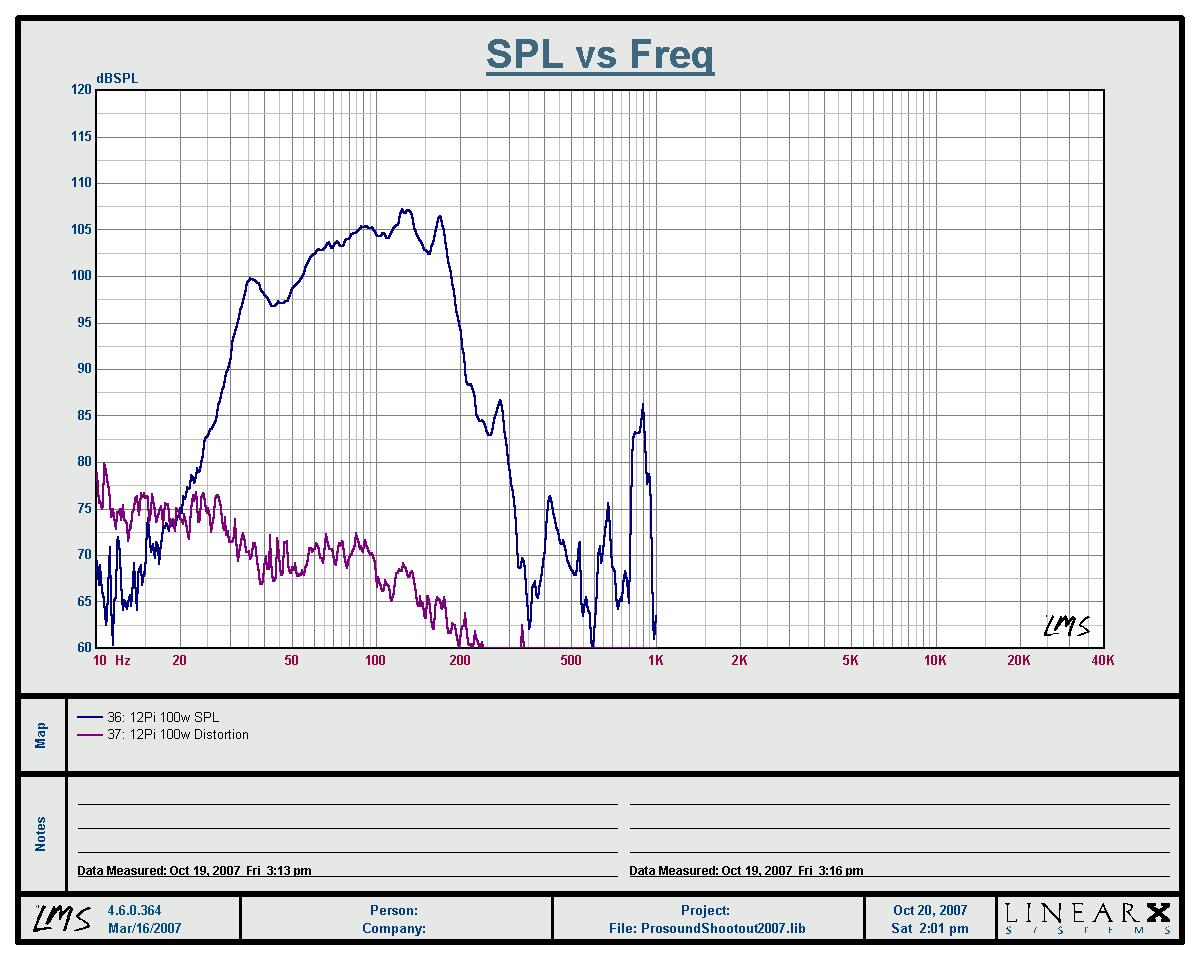

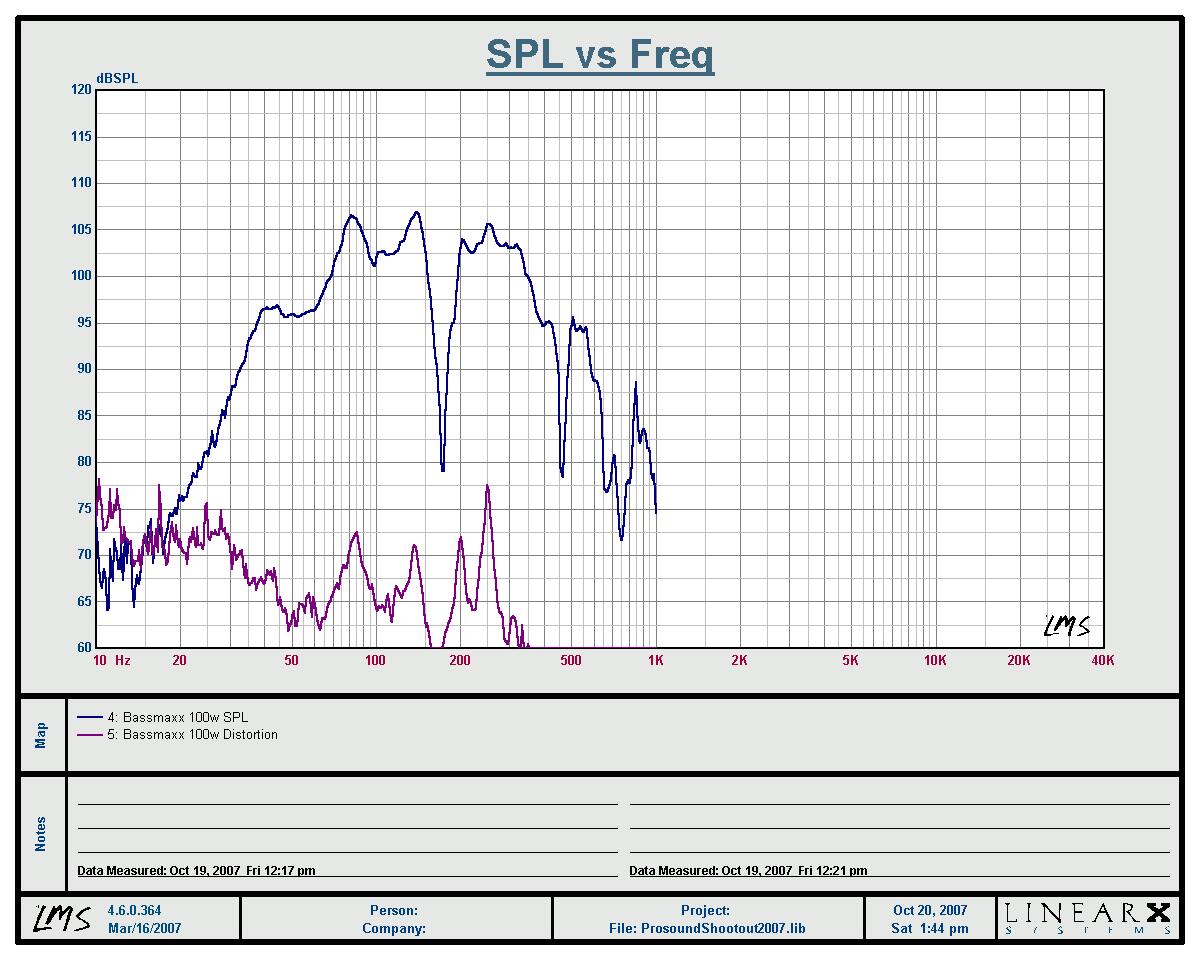

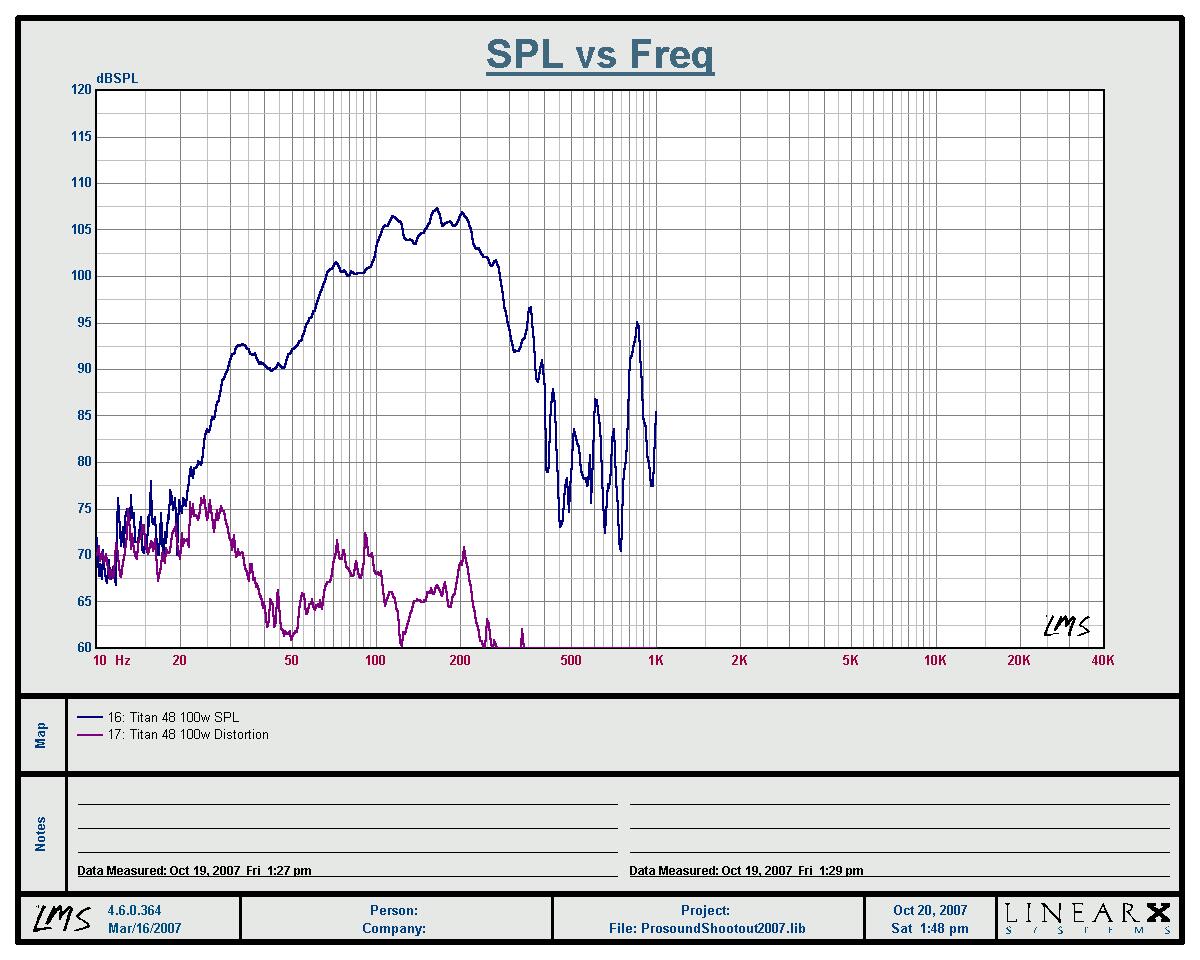

Below you'll see several response curves of various basshorns. Some have a single driver, others have two. But only one has dual-drivers configured push-pull. This helps isolate the benefits, and to identify them with the push-pull drive. SPL is shown in blue and distortion in violet. Pay attention to the distortion curves, which tell the story:

At 100 watts, most have low distortion:

12π, 100 watts @ 10 meters

12π, 100 watts @ 10 meters

Bassmaxx Deuce, 100 watts @ 10 meters

Bassmaxx Deuce, 100 watts @ 10 meters

Bassmaxx Z5, 100 watts @ 10 meters

Bassmaxx Z5, 100 watts @ 10 meters

Fitzmaurice Titan 48, 100 watts @ 10 meters

Fitzmaurice Titan 48, 100 watts @ 10 meters

Fitzmaurice Tuba 24, 100 watts @ 10 meters

Fitzmaurice Tuba 24, 100 watts @ 10 meters

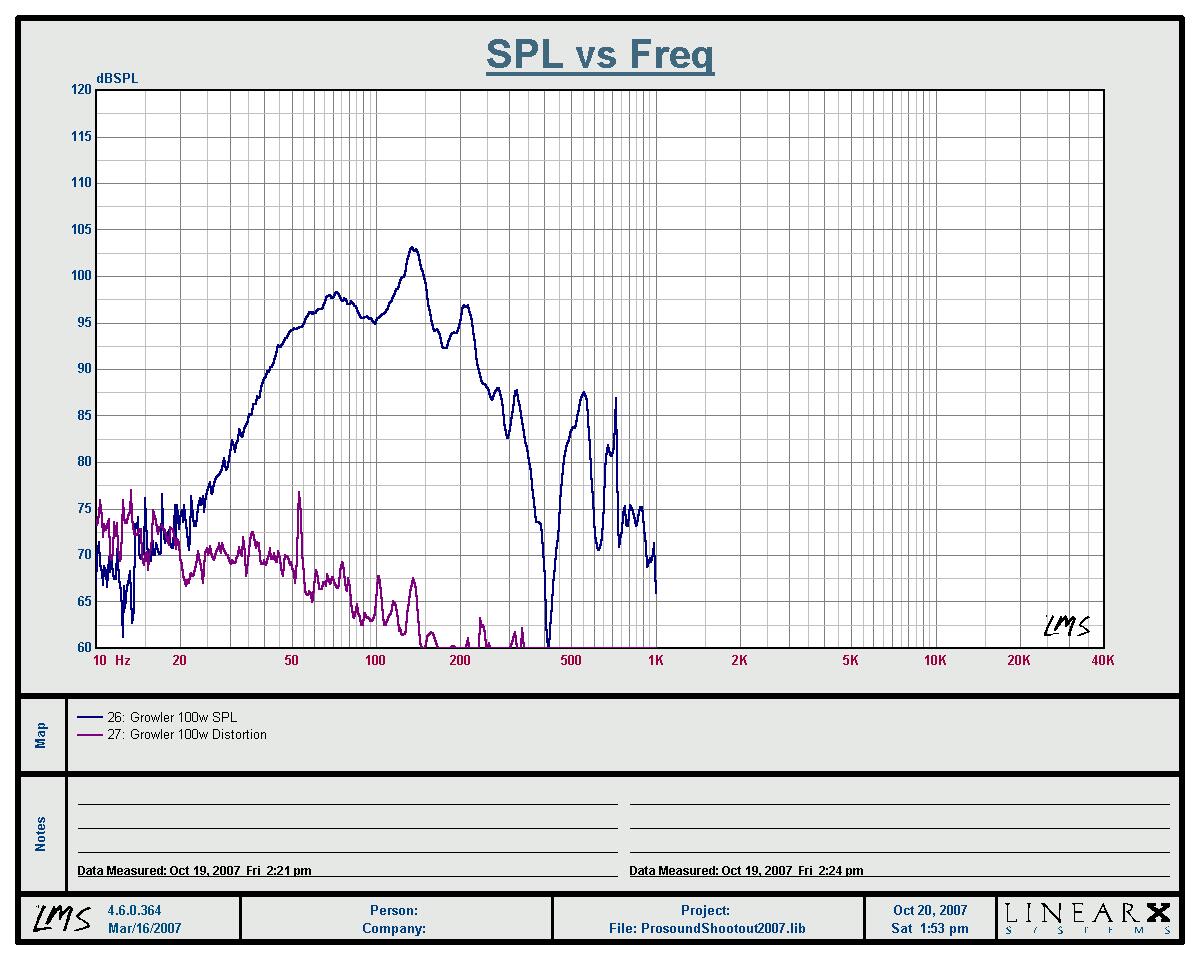

JTR Growler, 100 watts @ 10 meters

JTR Growler, 100 watts @ 10 meters

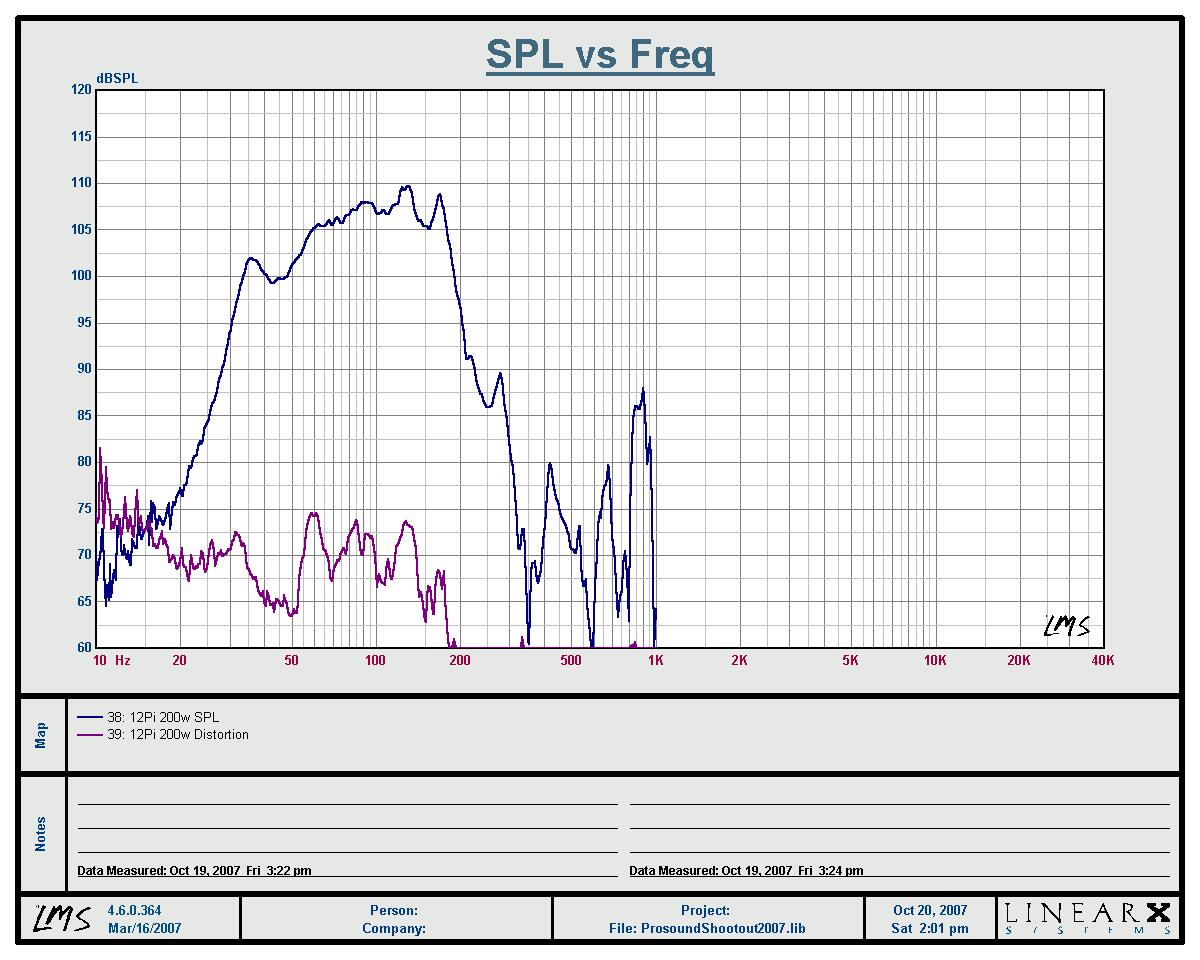

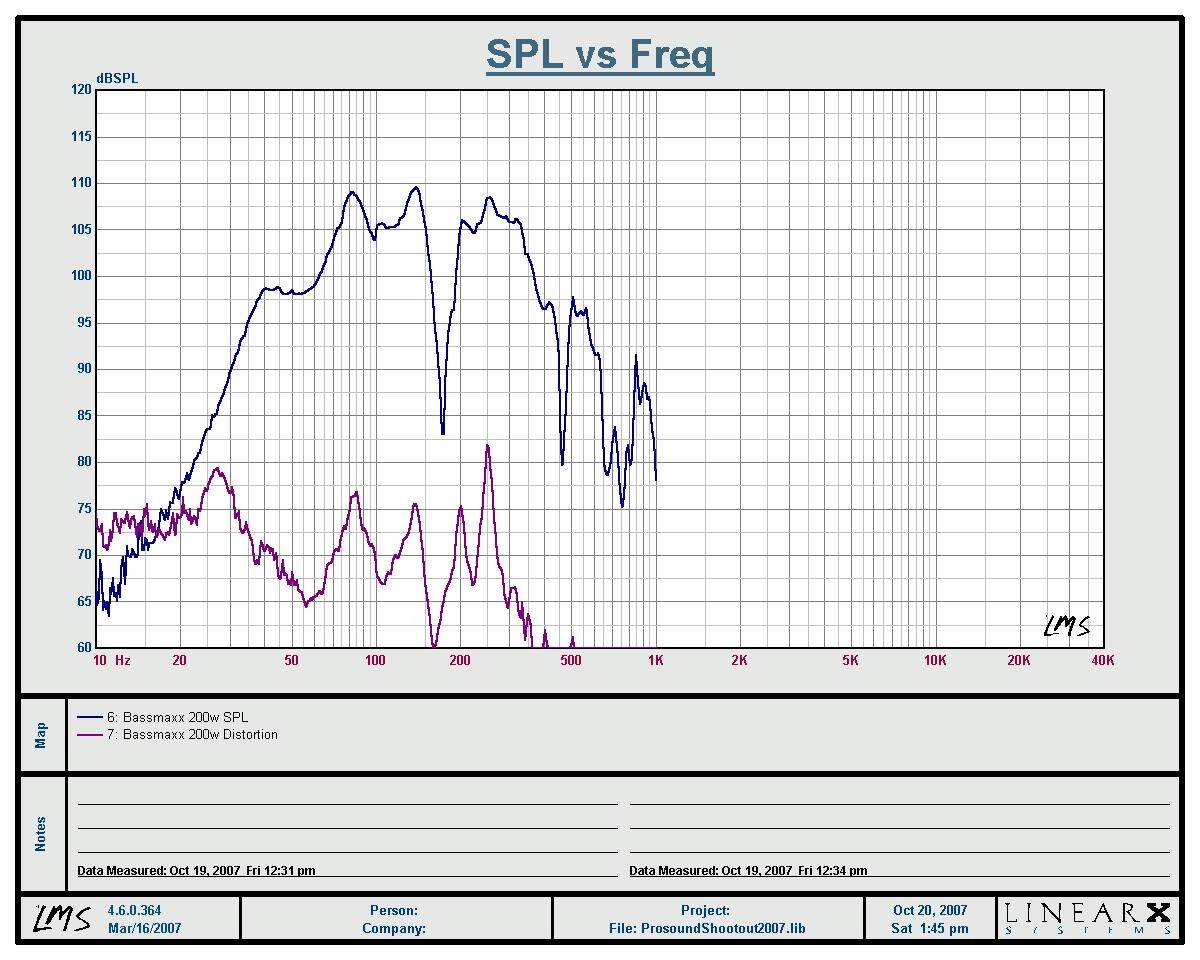

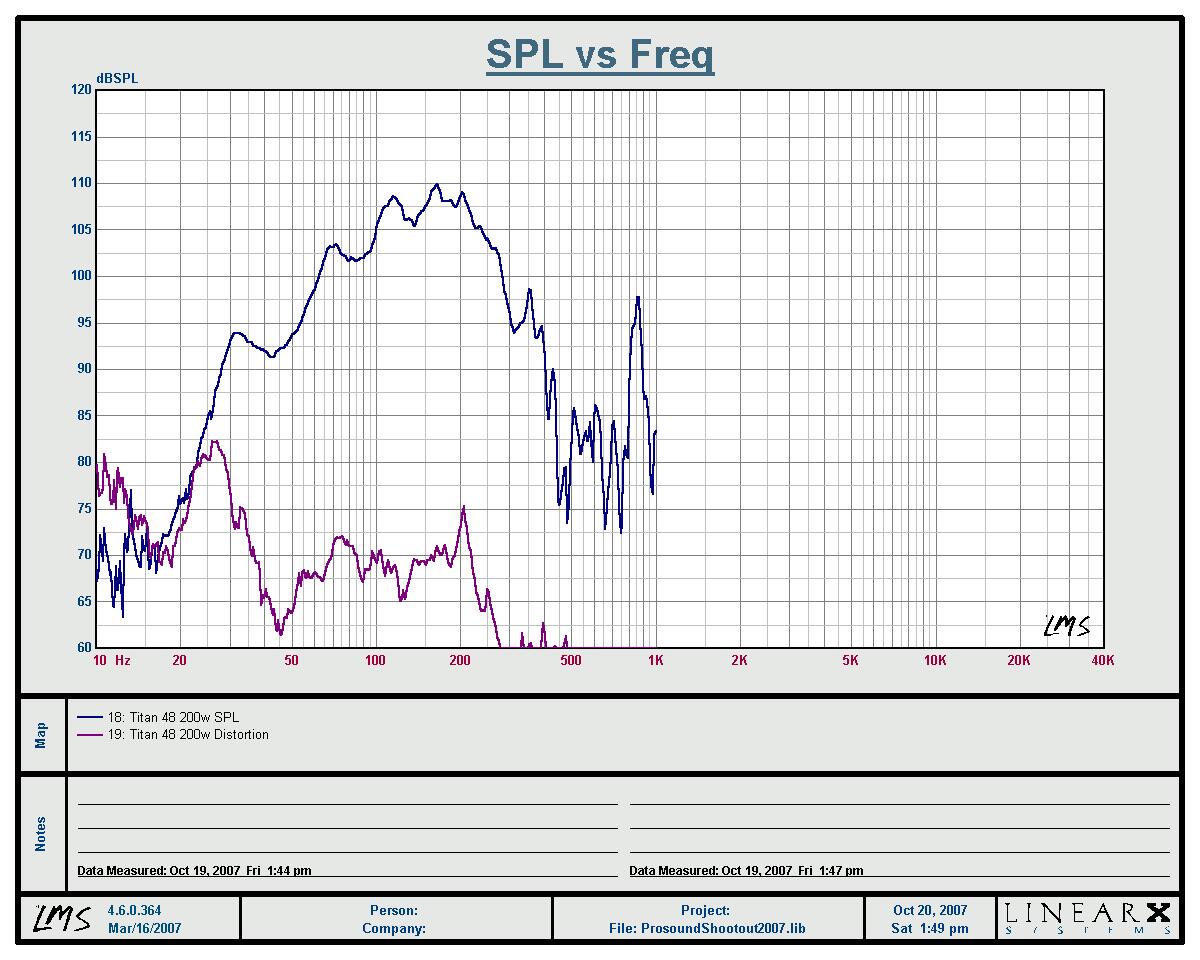

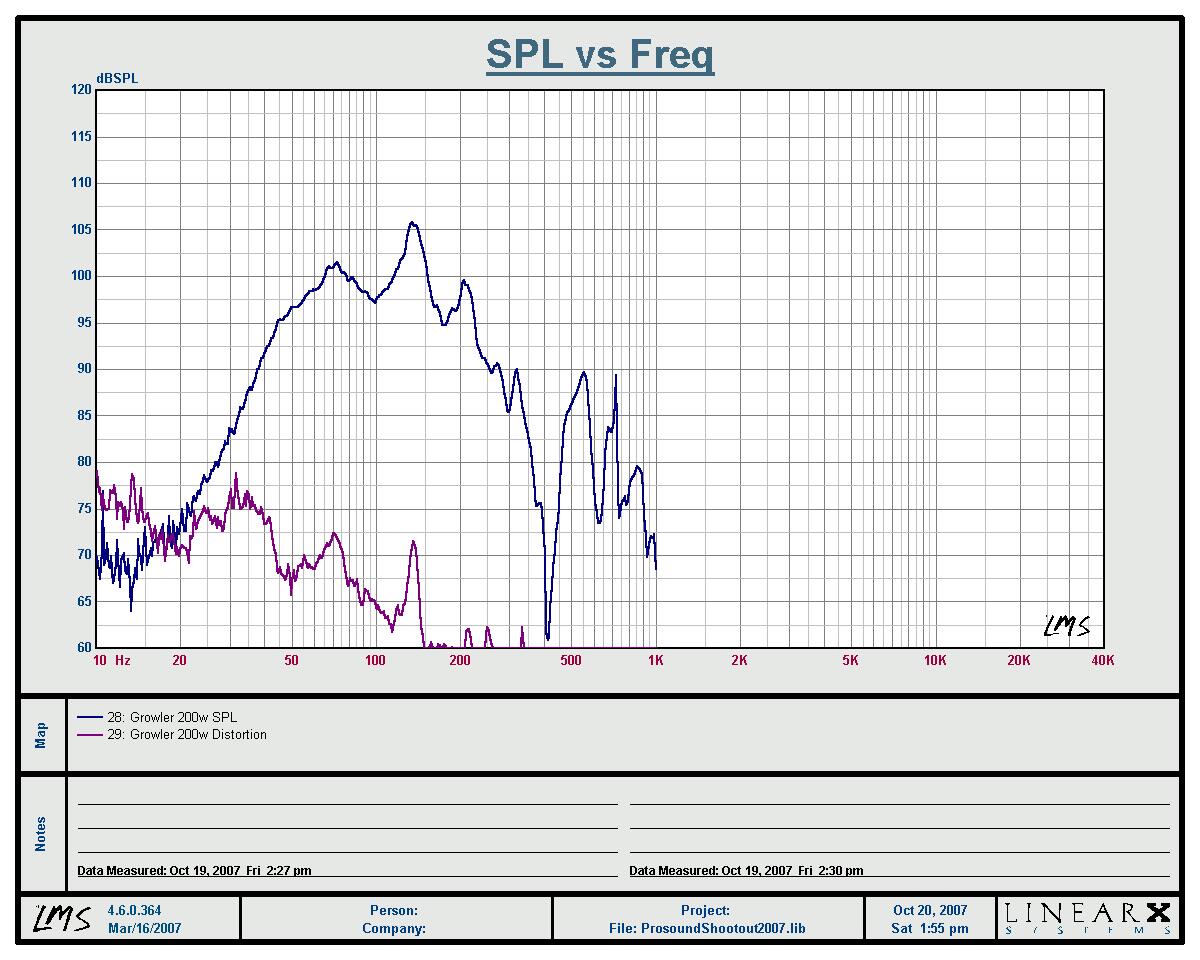

Still loafing at 200 watts, distortion starts to come up on some but not too bad:

12π, 200 watts @ 10 meters

12π, 200 watts @ 10 meters

Bassmaxx Deuce, 200 watts @ 10 meters

Bassmaxx Deuce, 200 watts @ 10 meters

Bassmaxx Z5, 200 watts @ 10 meters

Bassmaxx Z5, 200 watts @ 10 meters

Fitzmaurice Titan 48, 200 watts @ 10 meters

Fitzmaurice Titan 48, 200 watts @ 10 meters

Fitzmaurice Tuba 24, 200 watts @ 10 meters

Fitzmaurice Tuba 24, 200 watts @ 10 meters

JTR Growler, 200 watts @ 10 meters

JTR Growler, 200 watts @ 10 meters

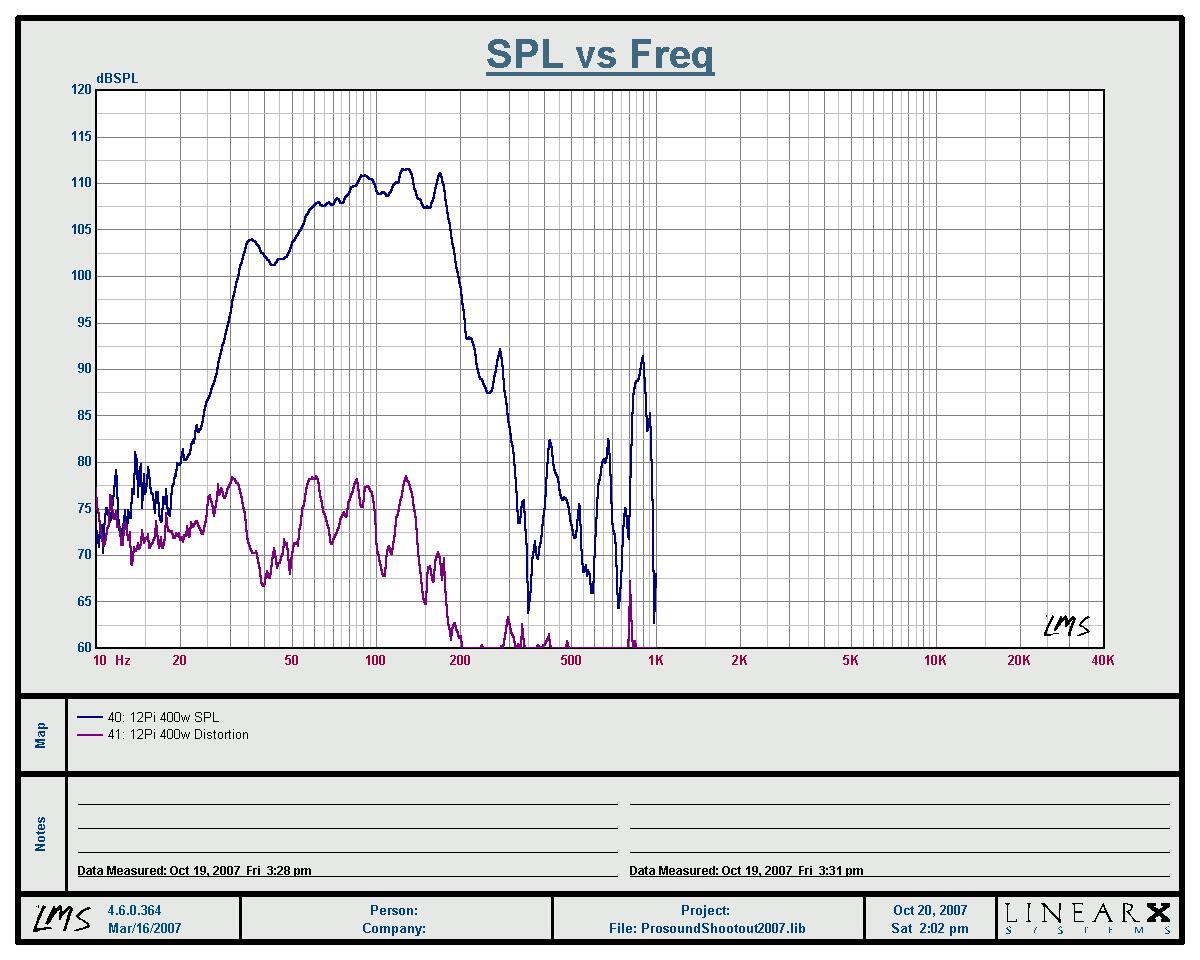

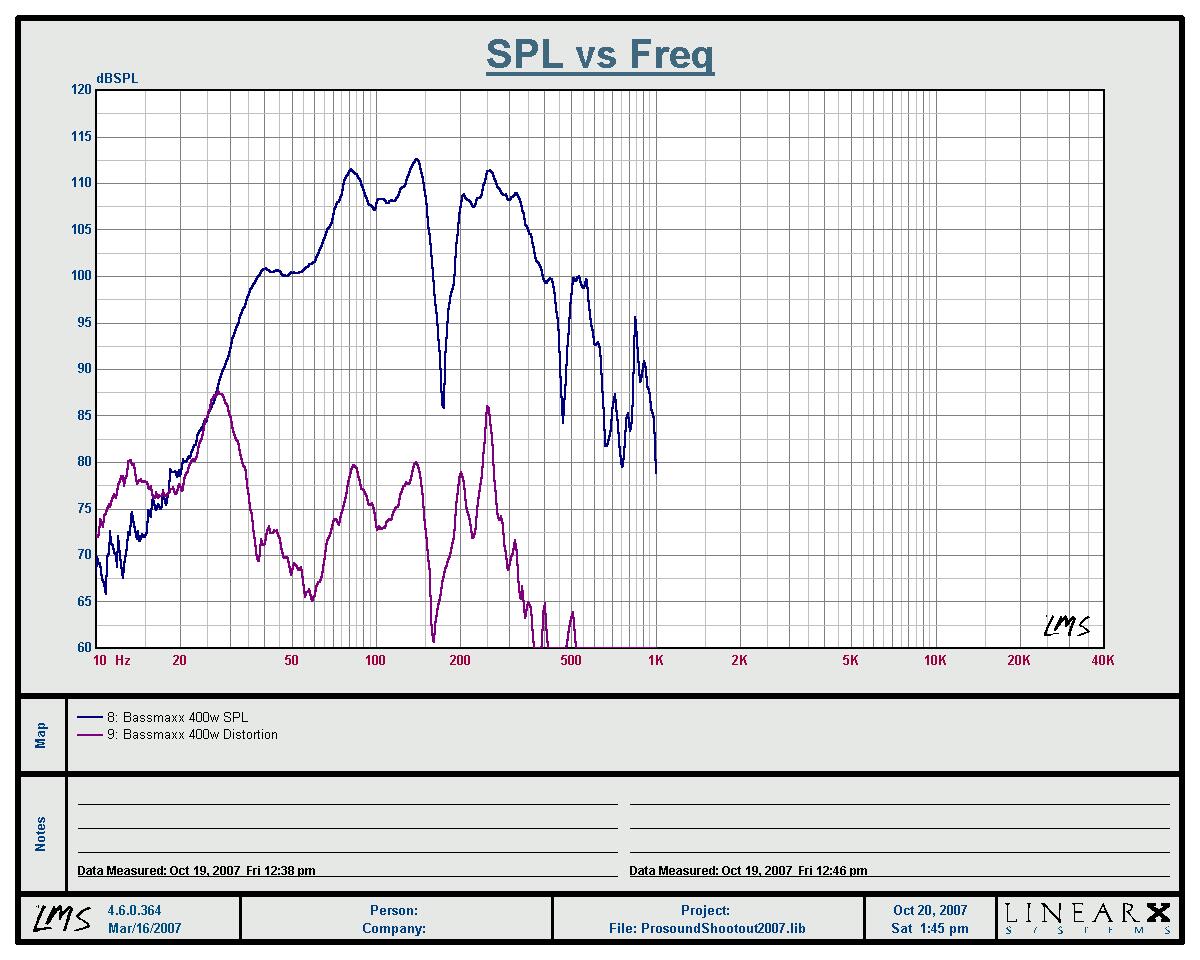

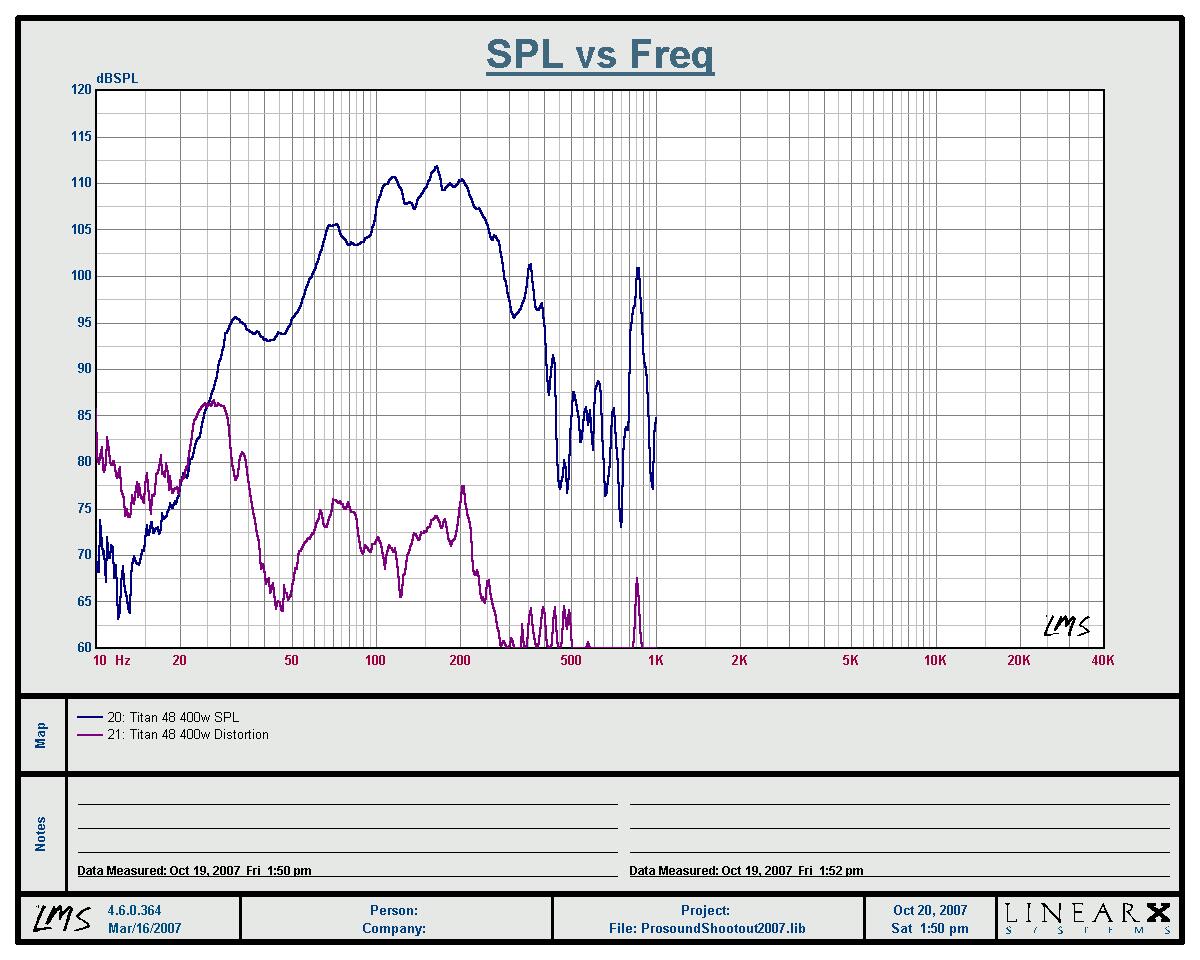

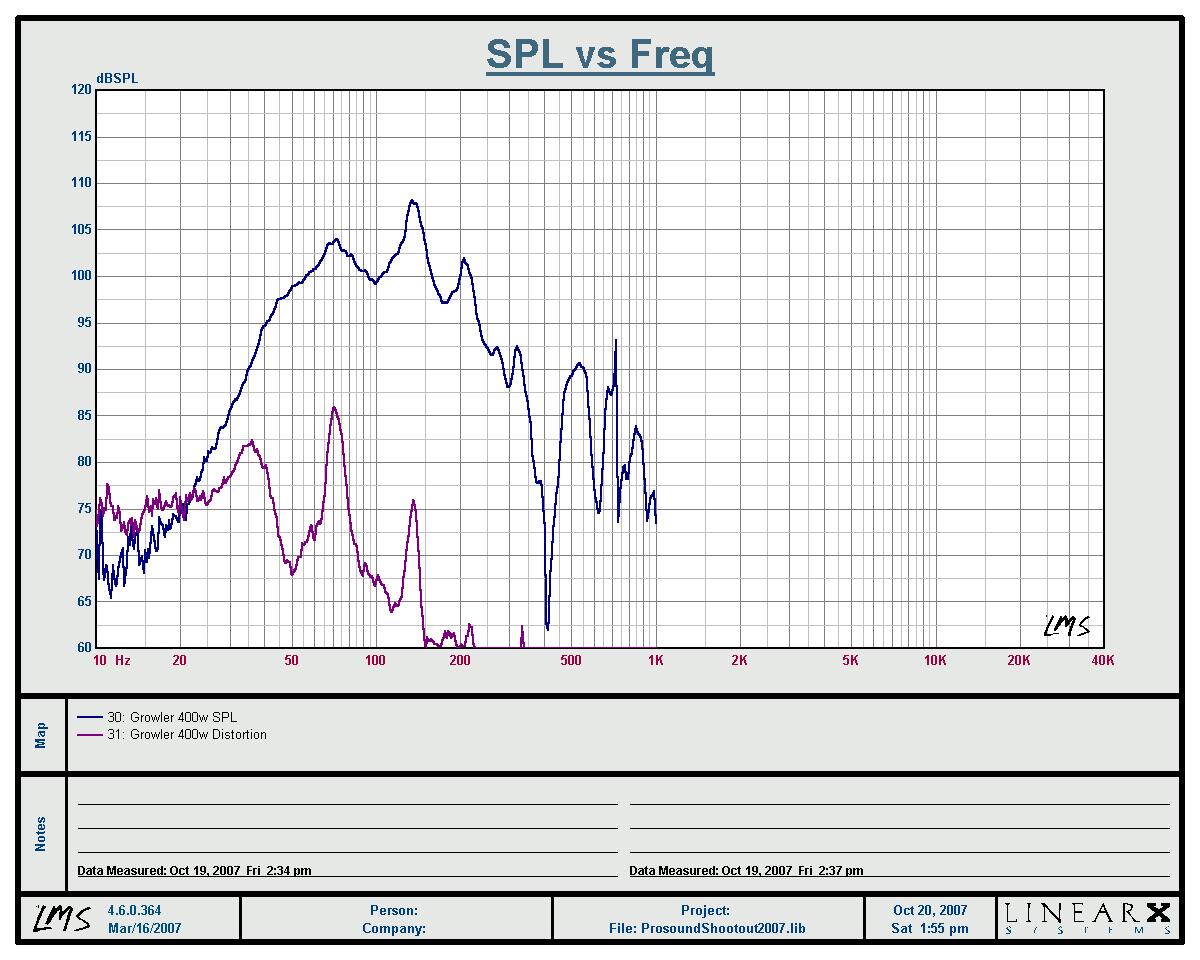

400 watts is where you really start to see distortion begin to rise. It's not a lot of power, but heat and excursion start to have an effect. Pay attention to the lowest frequencies. Distortion rises from asymetrical cone motion and response shape begins to change slightly from heat.

12π, 400 watts @ 10 meters

12π, 400 watts @ 10 meters

Bassmaxx Deuce, 400 watts @ 10 meters

Bassmaxx Deuce, 400 watts @ 10 meters

Bassmaxx Z5, 400 watts @ 10 meters

Bassmaxx Z5, 400 watts @ 10 meters

Fitzmaurice Titan 48, 400 watts @ 10 meters

Fitzmaurice Titan 48, 400 watts @ 10 meters

Fitzmaurice Tuba 24, 400 watts @ 10 meters

Fitzmaurice Tuba 24, 400 watts @ 10 meters

JTR Growler, 400 watts @ 10 meters

JTR Growler, 400 watts @ 10 meters

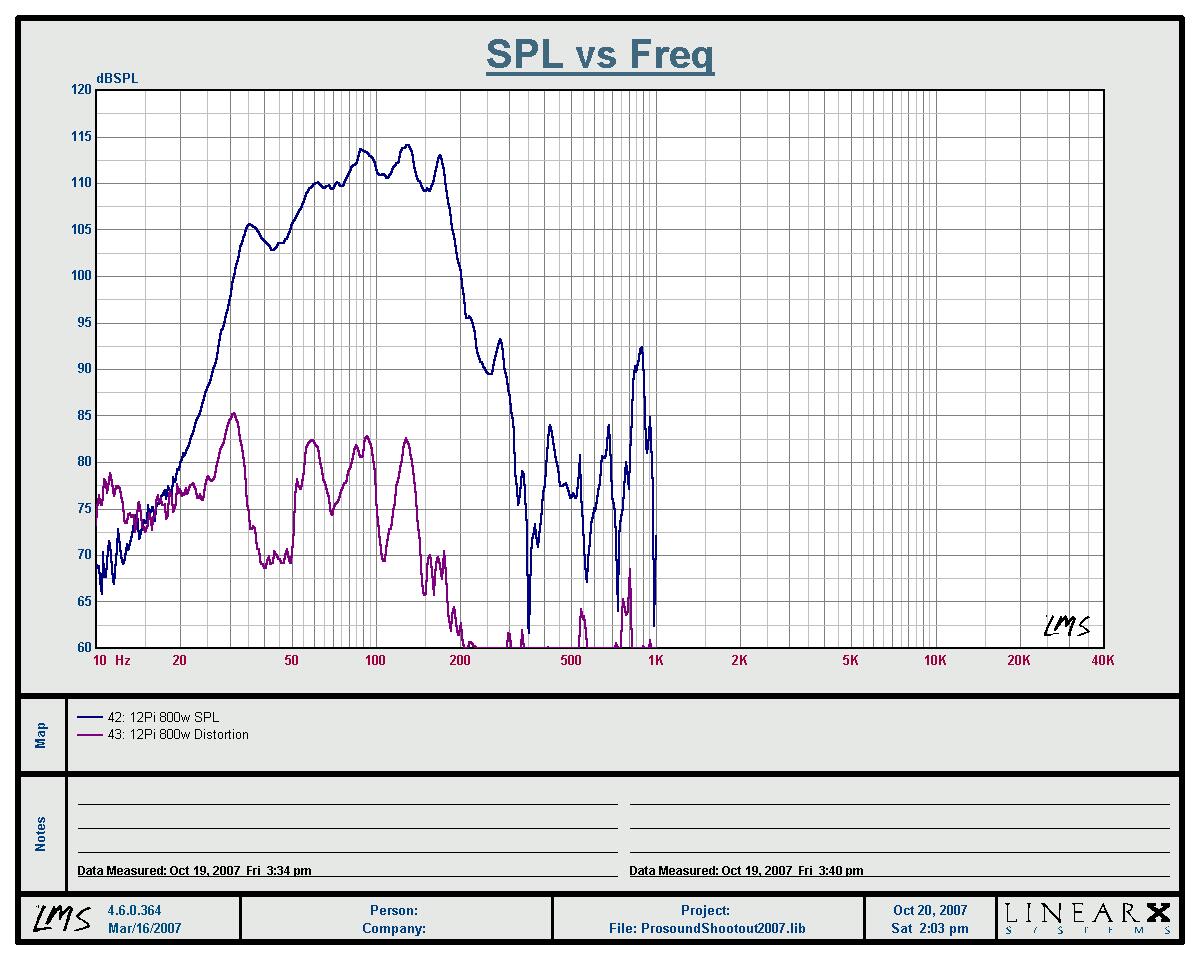

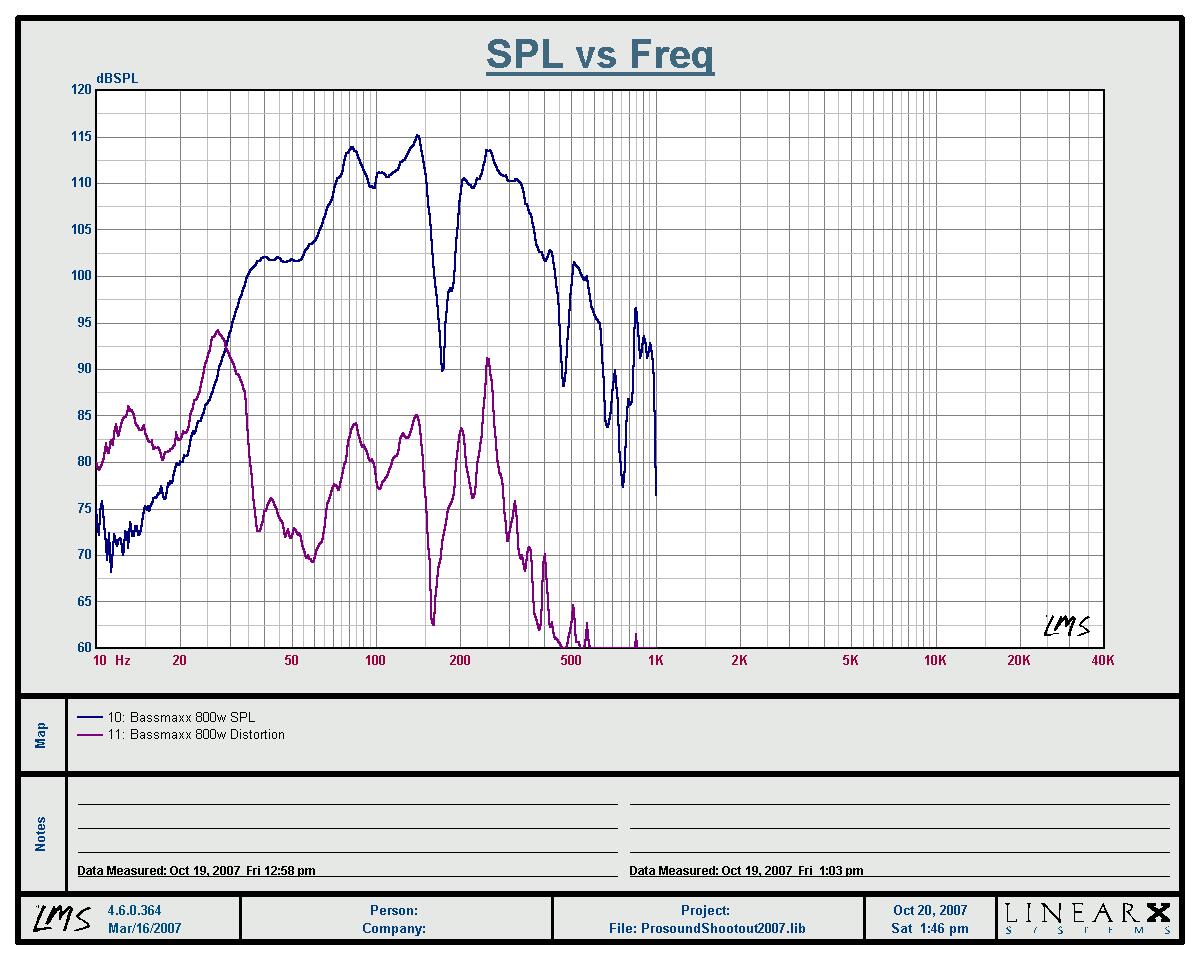

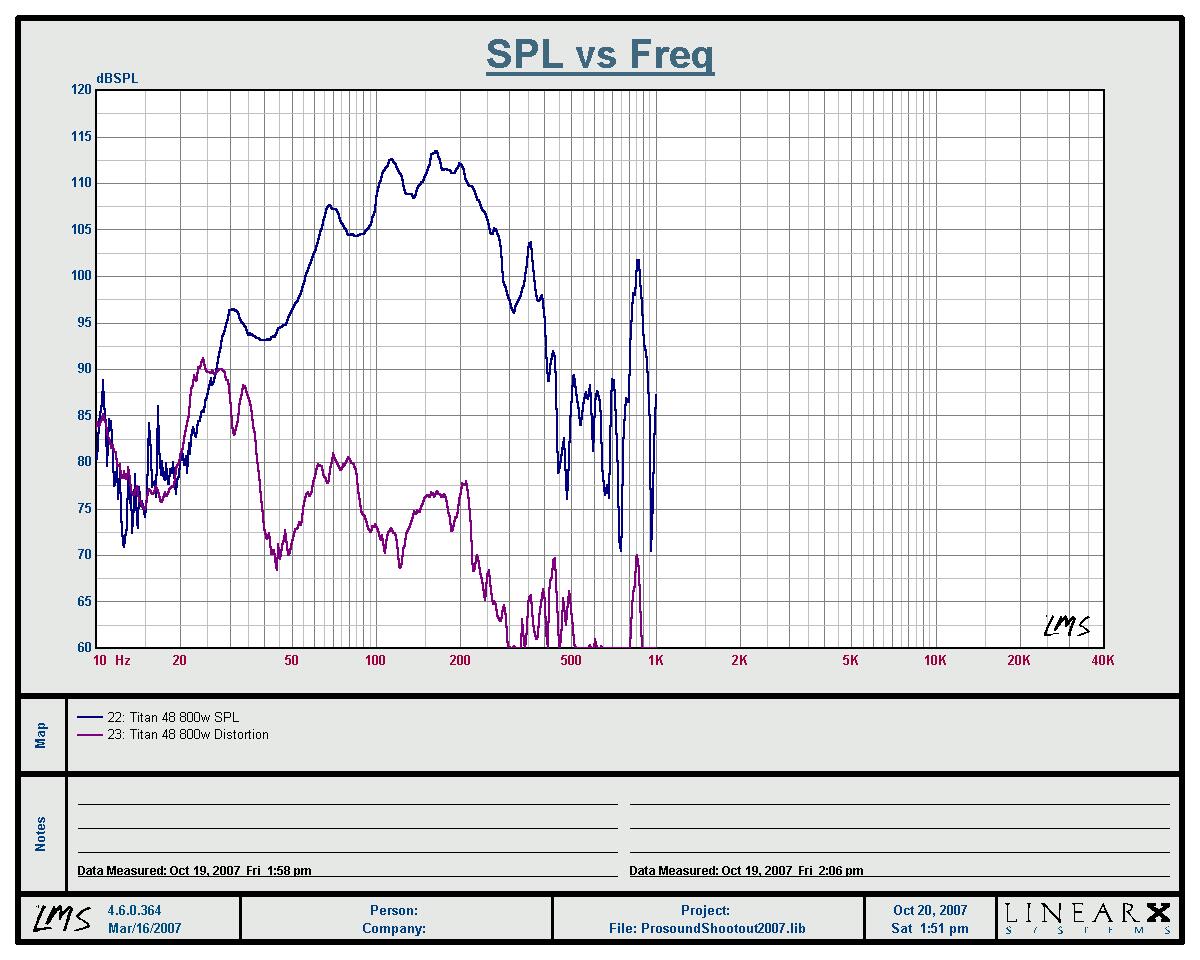

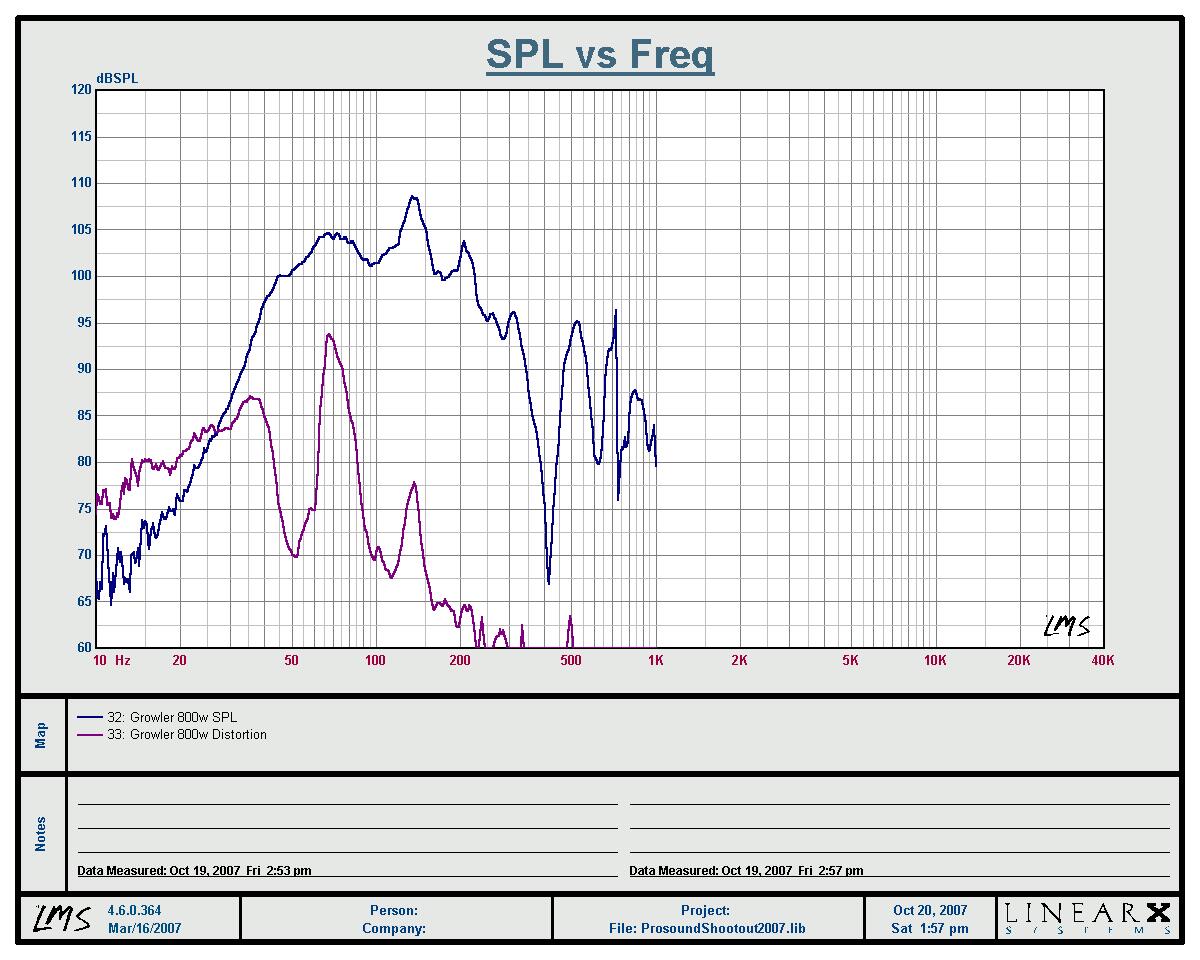

Thermal effects are more evident at 800 watts. Distortion is quite noticeable too. The fact that the one push-pull design in this lineup exhibits lower distortion than the others is evidence that cone motion asymmetry is responsible for a great deal of distortion. The push-pull configuration is effective at cancelling this kind of distortion, and horn folds attenuate higher harmonics.

12π, 800 watts @ 10 meters

12π, 800 watts @ 10 meters

Bassmaxx Deuce, 800 watts @ 10 meters

Bassmaxx Deuce, 800 watts @ 10 meters

Bassmaxx Z5, 800 watts @ 10 meters

Bassmaxx Z5, 800 watts @ 10 meters

Fitzmaurice Titan 48, 800 watts @ 10 meters

Fitzmaurice Titan 48, 800 watts @ 10 meters

Fitzmaurice Tuba 24, 600 watts @ 10 meters

Fitzmaurice Tuba 24, 600 watts @ 10 meters

JTR Growler, 800 watts @ 10 meters

JTR Growler, 800 watts @ 10 meters

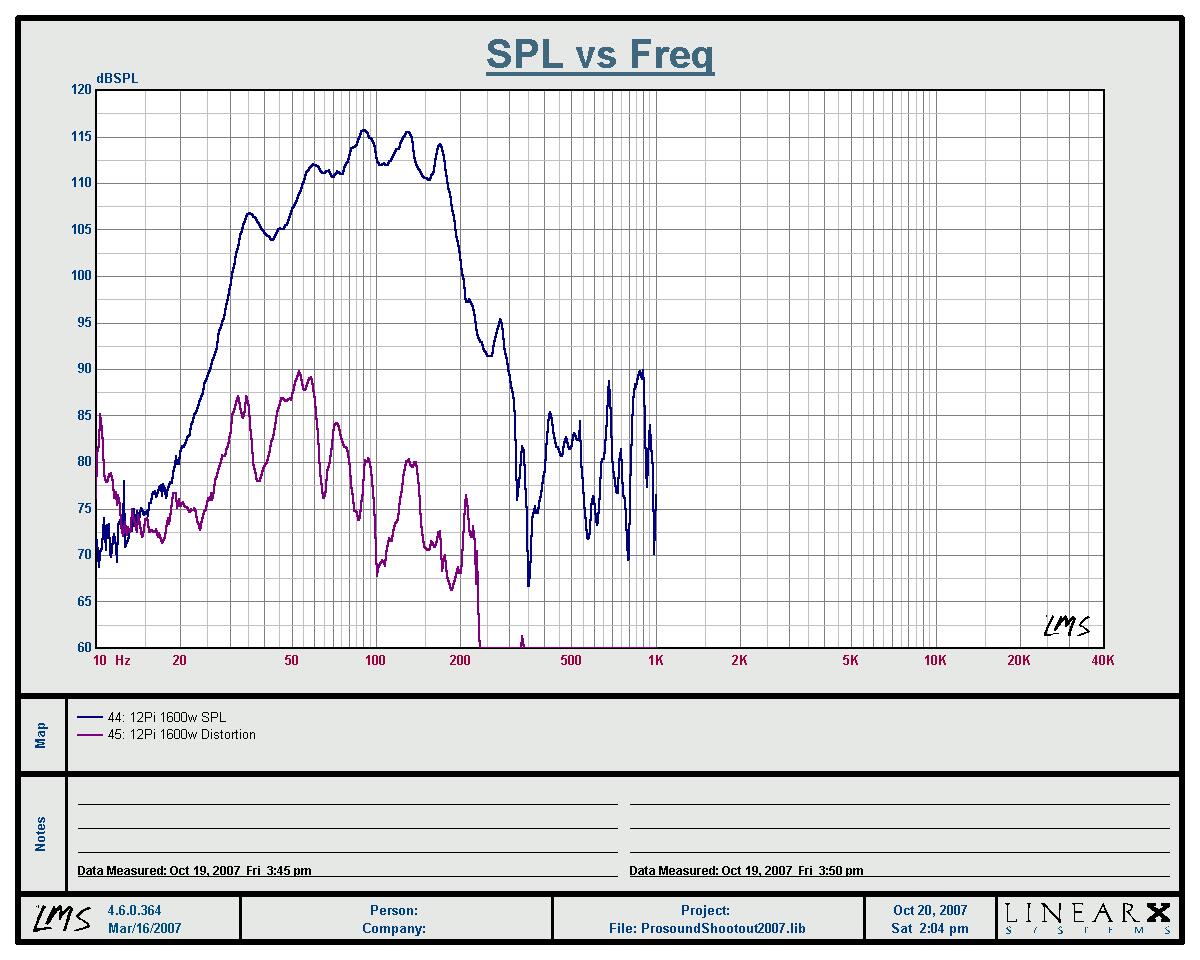

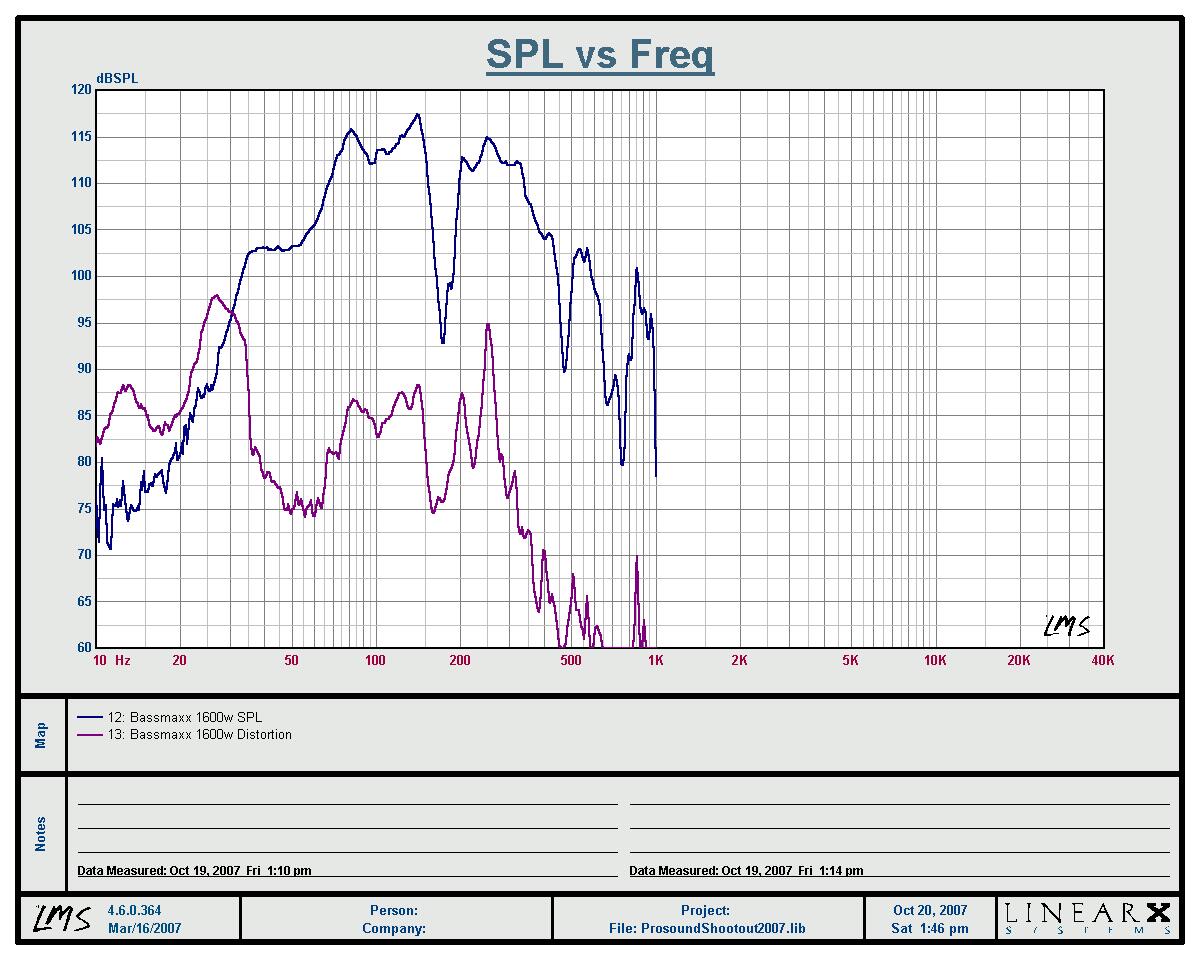

Thermal effects are clearly evident at 1600 watts. Distortion is much higher too. In fact, most basshorns have distortion louder than the fundamental at low frequencies near horn cutoff at high power levels. Not so with the 12π because of its push-pull drive.

12π, 1600 watts @ 10 meters

12π, 1600 watts @ 10 meters

Bassmaxx Deuce, 1600 watts @ 10 meters

Bassmaxx Deuce, 1600 watts @ 10 meters

Bassmaxx Z5, 1200 watts @ 10 meters

Bassmaxx Z5, 1200 watts @ 10 meters

If the cooling plugs aren't properly installed in the 12π, it will not survive a 1600 watt sweep. LABhorns will not survive this test for the same reason, unless cooling plugs are added. With cooling plugs, the thermal effects are minimized, even at this power level.

|

|

|

|

| Comparison with the LABhorn [message #51551 is a reply to message #51497] |

Fri, 16 November 2007 15:07   |

|

Wayne Parham

Wayne Parham

Messages: 19000

Registered: January 2001

|

Illuminati (33rd Degree) |

|

|

I did a quick search of the internet to find the LABhorn distortion measurements from the Michigan shootout in 2003. There are some differences between the Tulsa data and the Michigan data that make this less than an "apples to apples" comparison, but I think it is still good information.

The graph below is distortion of a LABhorn measured with "9-12 volts input". I'm not sure why the voltage wasn't recorded more precisely than that, but in any case, that's less than 40 watts.

Since the LABhorn presents about 4Ω load impedance, 9 volts is 20 watts and 12 volts is 36 watts. We're only talking about 10 to 20 watts per woofer being sent for the distortion measurements. I wouldn't expect much distortion at these power levels, because they're so low.

As you can see, even at just 10v, distortion at 25Hz is already at 10%, rising rapidly at frequency falls. As one would expect from a basshorn, it is lowest in the passband, but rises rapidly at the cutoff frequency. From 35Hz down, distortion ramps up heavily, already above 3% at 30Hz even at the low drive level of 10v. By 20Hz, it is at 30% distortion, again, at only 10v input signal.

These figures aren't unexpected. If you double the drive signal, you'd see that distortion would be louder than the fundamental at 20Hz, probably also at 25Hz. At 30Hz, distortion might be about equal to the fundamental, or maybe slightly less. If you increase drive even more, nearing maximum power, distortion of the LABhorn would be even worse. This is no slam of the LABhorn, all basshorns are like this. They work best when used in their passbands, and as you get close to their lower cutoff frequency, distortion rises rapidly. That's just the way it is.

Except for the 12π with its push-pull drive. Look at the charts below. The blue line is SPL and the violet line is distortion. This is a single horn, run at 100 watts - four times as much power as was used to test the LABhorn.

Distortion is so low at this power level that we really can't see it because it's below the noise floor. The violet line shows the noise floor, so you can't really say what level the distortion is, only that it is below 1% across the entire chart.

The distortion curve is shown in decibels, and to convert these values to percentages use the chart at the link below. The noise floor was about 70dB, so anything below that is indeterminate.

One thing that is clearly evident is the absense of distortion at very low frequencies. Distortion from most subwoofers rises rapidly below a certain point where cone motion becomes uncontrolled. Notice that distortion from the 12π hornsub doesn't rise at low frequencies like it does on other basshorns without push-pull drive. This makes a cleaner, tighter sounding bass. Everyone notices the difference in sound right away.

Now for the real nut cutter. How does the performs at high power levels. To illustrate, let's take the measurements on the other end of the scale, where distortion is at its worst. You really have to hit the 12π's with several hundred watts before distortion starts to creep up above the noise floor. So lets look at the 12π chart taken at 1600 watts:

Now you can see some distortion rising above the noise floor. See down there at 10Hz? It has started rising there. You also see some at 30Hz and 50Hz, about 20dB below the fundamental, which is about 10%. So by 1600 watts, we're seeing 10% distortion. It stays under 10% down all the way to about 20Hz, where it finally rises. Below 20Hz, the horn is actually very quiet, there's not much output either fundamental or distortion, but as you can see from the chart, at 1600 watts, you don't want to push 10Hz through them. That's not what they're designed for anyway.

Now let's compare that to the LABhorn, shall we? We can't do the same 1600 watt sweep we did in Tulsa, because LABhorns won't survive it. Not a single sweep. If you set the amplifier voltage for 65v and run a sweep, you'll smoke the drivers before the sweep ends. Without cooling plugs, the LAB12's just won't survive it. I know, I've tested these things a lot, and the stock LAB12 just won't do it.

The measurements from the Michigan shootout show the LABhorn produces 30% distortion at 20Hz with only 25 watts input. Distortion from a 12π basshorn subwoofer doesn't rise to this level until it reaches a thundering 1600 watts. That's 64 times more power!

Even with just the 25 watt chart for the LABhorn, we can clearly see a difference in the LABhorn and the 12π basshorn subwoofer. Where the distortion rises below 35Hz in the LABhorn, it rises much more slowly in the 12π. The same distortion you're getting from LABhorns at 25 watts, you don't see in the 12π until it reaches 1600 watts.

The push-pull arrangement is most effective at very low frequencies. It is designed to be of most benefit near cutoff, where the horn is starting to lose its ability to load the cone. It does that beautifully, as the data clearly shows.

|

|

|

|

| Re: 12π basshorn subwoofer - the best yet! [message #68319 is a reply to message #51551] |

Thu, 23 June 2011 17:21  |

|

Wayne Parham

Wayne Parham

Messages: 19000

Registered: January 2001

|

Illuminati (33rd Degree) |

|

|

I designed the 12π hornsub after some discussions on a hifi forum about the LABhorn. The LABhorn was initially designed as a DIY horn for prosound use with an intended passband of 30Hz to 100Hz. But as with many other things, someone proposed using it for home theater, and using EQ to boost the deepest bass to match the passband level. I responded to that saying I thought it was a really bad idea, because distortion would be through the roof. This cascaded into a fairly heated discussion about hornsub power, distortion and general bravado.

My position was that a horn tuned for 30Hz should probably only be used down to 30Hz, and that even at relatively low power levels, a 20Hz signal presented to it would create triple digit distortion. Then add to that the fact that they were going to boost the band below 30hz by 10dB+, it seemed to me to be an ugly proposition. I mean, I am a horn enthusiast, but this just wasn't a good idea to me. I even understand the spectacle of huge basshorns, how cool that is and all. I like big powerful motors and fast cars and motorcycles, all that good "guy" stuff. So I get the cool factor of basshorns in the man cave. But still, my position was that direct radiating subs tuned appropriately for the band, like reflex boxes tuned to 20Hz, would be better. I had begun to study and implement the Welti multisub approach around the same time, so I felt the best approach was multiple direct radiating subs, per Welti.

The LABhorn proponents were fairly zealous, and I equally so. Neither side really relented. They said the basshorn was so powerful, that at home theater levels it would be loafing. I said that at 5 watts of passband power, the (10dB+) EQ below 30Hz would bump that range up to 50 watts, making distortion rise to the triple digits, over 100%. They said I was just a naysayer, and I should be tarred and feathered. Then they asked me a key question, which was "what would you do?"

I had already told them what I would do in a home theater, which was multiple direct radiating subs, bass-reflex probably. Each box wouldn't have the output of a hornsub, but it would be more than adequate for the environment. They would be tuned appropriately for the passband, so distortion wouldn't be bad at moderate power levels. And of course, each box is much smaller than a hornsub, easy to place and quite good for a multisub configuration.

But then the question was rephrased, and I was asked, "what would you do to improve the LABhorn?"

At first, I disregarded the question, knowing it was rhetorical. It was just another argumentative forum post from a LABhorn lover.

As days passed, though, I realized that I could actually answer this question with a new design that addressed some of the weaknesses of the LABhorn. The 12π hornsub is that design.

There were three areas I was focused on. First was the lumpy response when used in singles or even small groups. I've designed a lot of horns, and I knew I could reduce the big dip the LABhorn had just above cutoff with careful front and rear chamber size, and possibly by making the mouth just a little larger. Second was to use push-pull drive to reduce the distortion at very low frequencies. And third was to improve cooling. The LABhorn suffered from thermal stress, but the common conception was that failures were excursion related. I knew I could make the drivers more robust by improving their cooling.

The LABhorn guys saw this effort as an attack, and the adversarial posture of the two "sides" widened even further. Pity, because there is so much overlapping development. I actually made the cooling plugs so they would fit the LABhorn, making easy retrofit possible. I initially had planned to use an entirely different layout, but by maintaining some of the same basic shape, it allowed cross-fitting of parts.

Changing the response to make it a little smoother was relatively easy. Hornresp is a mature program, and allows easy development of basshorns. You can expect acoustic measurements of your physical model to match the Hornresp model's predictions. So I was able to sim up an improved design within a short period of time.

The push-pull drive was kind of a no-brainer too. The LABhorn used two drivers, so it seemed natural for me that they be configured in push-pull. My thoughts were that passband distortion levels of a good basshorn were already very low, but push-pull couldn't hurt. Might shave a little more distortion. Down near cutoff, where the horn starts becoming more reactive and can't load the cone as well, I thought it might help even more. And below cutoff, where distortion skyrockets, I thought push-pull might keep distortion in check. There's not a lot of VLF content in a prosound event that would cause this distortion, where it might occur, high-pass filtering is probably wise. But whatever might be down there, push-pull will reduce distortion. So if someone just has to run a basshorn below cutoff, this is the one to do it with.

The cooling system was where I put the most effort. At first, I was under the impression, like many other people, that the best way to remove the heat was with forced-air convection. My assumption was that the air in the sealed rear chambers was getting hot, causing the cooling vents to lose effectiveness. So my first efforts involved ducting the vent to a heat exchanger to remove heat from the box. My biggest design problem for that first system was to introduce unidirectional flow so I could have a hot side and a cool side, but to do it in a way that didn't create an asymmetrical load on the cone. Couldn't valve it in a way that caused any pressure differential on alternating half cycles, or in fact, anywhere in the cycle. The acoustic load of whatever ducting arrangement I might create had to be perfectly uniform at all frequencies and all displacements.

The cooling system was where I put the most effort. At first, I was under the impression, like many other people, that the best way to remove the heat was with forced-air convection. My assumption was that the air in the sealed rear chambers was getting hot, causing the cooling vents to lose effectiveness. So my first efforts involved ducting the vent to a heat exchanger to remove heat from the box. My biggest design problem for that first system was to introduce unidirectional flow so I could have a hot side and a cool side, but to do it in a way that didn't create an asymmetrical load on the cone. Couldn't valve it in a way that caused any pressure differential on alternating half cycles, or in fact, anywhere in the cycle. The acoustic load of whatever ducting arrangement I might create had to be perfectly uniform at all frequencies and all displacements.

In truth, that was the easy part. I was able to make a "valve" that succeed in introducing unidirectional flow without causing any pressure difference in any part of the cycle. It used two orifices, each allowing laminar flow through it in one direction but causing turbulence in the other direction. One orifice was oriented to flow one way, the other allowed flow in the other direction. This made unidirectional flow without any change of pressure at any part of the cycle.

So that part was done, but the problem was that the air flowing through the vents wasn't all that hot. There was no energy to remove. The bursts of air were strong, so it isn't as though the air passing through the gap was too slow. That's really the key to forced air convection cooling - airflow. And the driver has plenty of that, of course, assuming excursion isn't limited by the acoustic load. But when the driver is moving, the venting is working well, and there just isn't a lot of heat to remove.

But what was hot was the pole piece. It would get hot enough to cook on during my tests. Before I gave up on it though, I tried putting the speaker in different ambient air temperatures, to simulate the heating of the air in a small rear chamber and also going the other way, refrigerated air just to see what effect there was. Nothing. The range of ambient temperatures matters if it changes by hundreds of degrees (as I later discovered), but not if only by a couple dozen.

So that's when I focused on that super-hot pole piece. I decided to make a plug that would contact the pole piece and wick heat away. I put holes in the plug so it wouldn't restrict the cooling air vent. The improvement was striking. I tested this extensively, going through a few drivers in the process, to find out exactly what the limits were, both on the bench and in a loudspeaker system. I eventually patented this system, because it worked so well.

What happens is the voice coil magnetism creates eddy currents in the steel pole pieces, which cause direct heating. It also radiates heat into the magnet structure and some heat is transferred by convection too. The motor core, its ceramic magnet and pole pieces being a thermally insulating material surrounding a metal core, form the perfect heat storage device, just like a Thermos bottle. Even if the voice coil is being cooled from cone motion, the motor core temperature will still rise to temperatures approaching the boiling point. This makes the local ambient temperature surrounding the voice coil be very high, shifting its operating point. The situation is made even worse when the driver is used in cabinets that limit excursion, like basshorns.

In the end, the cooling plug approach proved very effective. It is fairly simple to manufacture and implement, and especially in the case of the 12π hornsub, fits perfectly between the magnets and access panels. The panels then serve dual purpose, being both a way to access the drivers and also as a heat sink. Tests have shown that it increases power handling over 225%, making the 12π hornsub significantly more robust, particularly during long high-power events.

|

|

|

|

Goto Forum:

Current Time: Wed Feb 04 03:29:53 CST 2026

|