| Push-pull verses shorting rings [message #49653] |

Wed, 21 June 2006 15:18 |

|

Wayne Parham

Wayne Parham

Messages: 18998

Registered: January 2001

|

Illuminati (33rd Degree) |

|

|

I've received a lot of E-mails about the 12π recently, mostly about its heat exchanger and the reasons for choosing the push-pull drive configuration. We discussed these things at some length last year, but I guess it's a good time to look back over the 12π development history.

When a speaker is pushed hard, its drive force is increasingly non-linear. The causes are mostly due to heat and magnetic flux modulation. The force that moves the cone is not perfectly linear, and its back and forth motion is not perfectly symmetrical. This is because the magnetic field generated by the voice coil deforms the magnetic field of the fixed magnet. This causes eddy currents in the magnetic circuit, literally modulating the flux. Further, the magnetic circuit is made of several parts, the center pole, top plate and back plate, in addition to the magnet itself. These may saturate at different levels, which will also cause force asymmetry. These are the primary causes of distortion in a loudspeaker.

Shorting rings correct the drive force by counteracting flux modulation. To do this, a shorting ring is installed so that the electromagnetic field generated from the voice coil induces a current within the shorting ring. The current flowing through the shorting ring creates its own magnetic field. If the shorting ring is properly sized and placed, it will create a force that is equal and opposite to the flux difference. The idea is to counteract flux modulation, so that the force in both directions is the same.

I had originally asked Eminence to investigate the possibility of putting a shorting ring into a subwoofer to reduce harmonic distortion. This would be used as the motor for high-performance subwoofer designs. JBL has been very successful with this technology and even though the distortion reduction works best above 100Hz, they have been able to reduce distortion at subwoofer frequencies as well. So I had hoped Eminence might be able to build an improved subwoofer too.

Eminence found that they were unable to get significant distortion reduction below 150Hz from a shorting ring. The reason is pretty simple - The shorting ring works like a transformer winding, and it has to inductively couple enough energy to create a magnetic field large enough to offset the difference in force caused by flux modulation. As frequency goes down, this becomes harder and harder to do and the size of the ring becomes prohibitively large. The volume displaced by the ring makes magnet size smaller so more magnet has to be added to compensate and the requirements become a vicious cycle. So there just isn't enough "meat" to make a good flux stabilized subwoofer.

Another solution presents itself, and that is the push-pull configuration. Push-pull drive is pretty simple to implement, from an engineering perspective. All you have to do is take two identical motors and run them in opposite directions. Position them so that the drive force combines in an additive fashion, and voila! You have push-pull drive. Any asymmetries in an individual drive unit will cancel by using complementary pairs. Essentially you have a strong motor and a weak motor on each half cycle. On each contiguous half cycle, the strong one and the weak one flip.

This can be as simple as taking two identical loudspeakers and running one backwards on the baffle. You have to also reverse polarity on the reverse-mounted driver so their acoustic outputs are in phase. Best results are obtained when the drivers are matched.

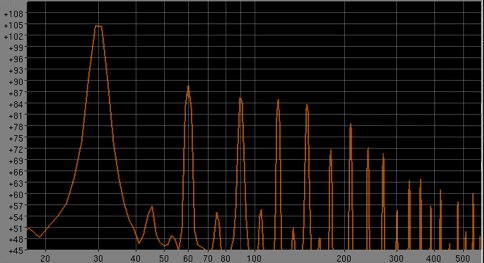

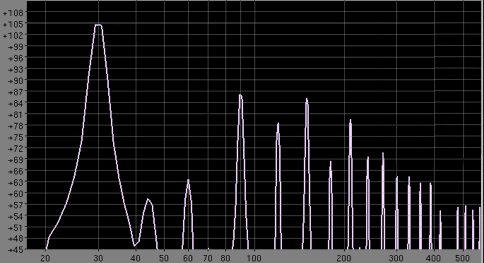

For example, see the harmonic spectrum charts below:

Harmonic Spectrum of (top) dual woofers on a baffle and (bottom) push-pull woofers on baffle

Harmonic Spectrum of (top) dual woofers on a baffle and (bottom) push-pull woofers on baffle

The charts above show the harmonic spectrum of a high-power 30Hz sine applied to a pair of identical woofers on a baffle. The chart on the right has the woofers mounted in push-pull. Notice that the second harmonic is 25dB lower than the dual-woofer configuration that doesn't employ push-pull drive.

You can also take two identical motors run in opposite directions and physically connect them to a common point on a diaphragm. This is another approach that does the same thing. In either case, the solution is essentially mechanical, using two drive units. Each one alternates between being slightly stronger and slightly weaker on each half cycle. The net force is equalized by having them work as a complementary pair.

The push-pull configuration is easy to implement because it can be accomplished with standard drivers. It works best at low frequencies with drivers physically close together, especially when operated in a common chamber. The further apart they are, the less coupling is provided. So the push-pull arrangement is very well suited to subwoofers whereas shorting rings are better suited for midbass, midrange and higher frequency drivers.

Push-pull drive is particularly attractive when used in a horn subwoofer. The front chamber and mass-rolloff tend to reduce third and higher harmonics. Push-pull drive reduces the second harmonic. This in addition to the already low distortion due to reduced excursion from horn loading. Horn subwoofers with push-pull drive offer excellent low-distortion performance even at very high power levels.

|

|

|

|