| Re: Modifed 4 Pi Build Report [message #68570 is a reply to message #68569] |

Fri, 15 July 2011 23:56   |

Dave_S

Dave_S

Messages: 28

Registered: April 2011

|

Chancellor |

|

|

Here are a few images of the build. I chose baltic birch for the sides and a cherry veneer.

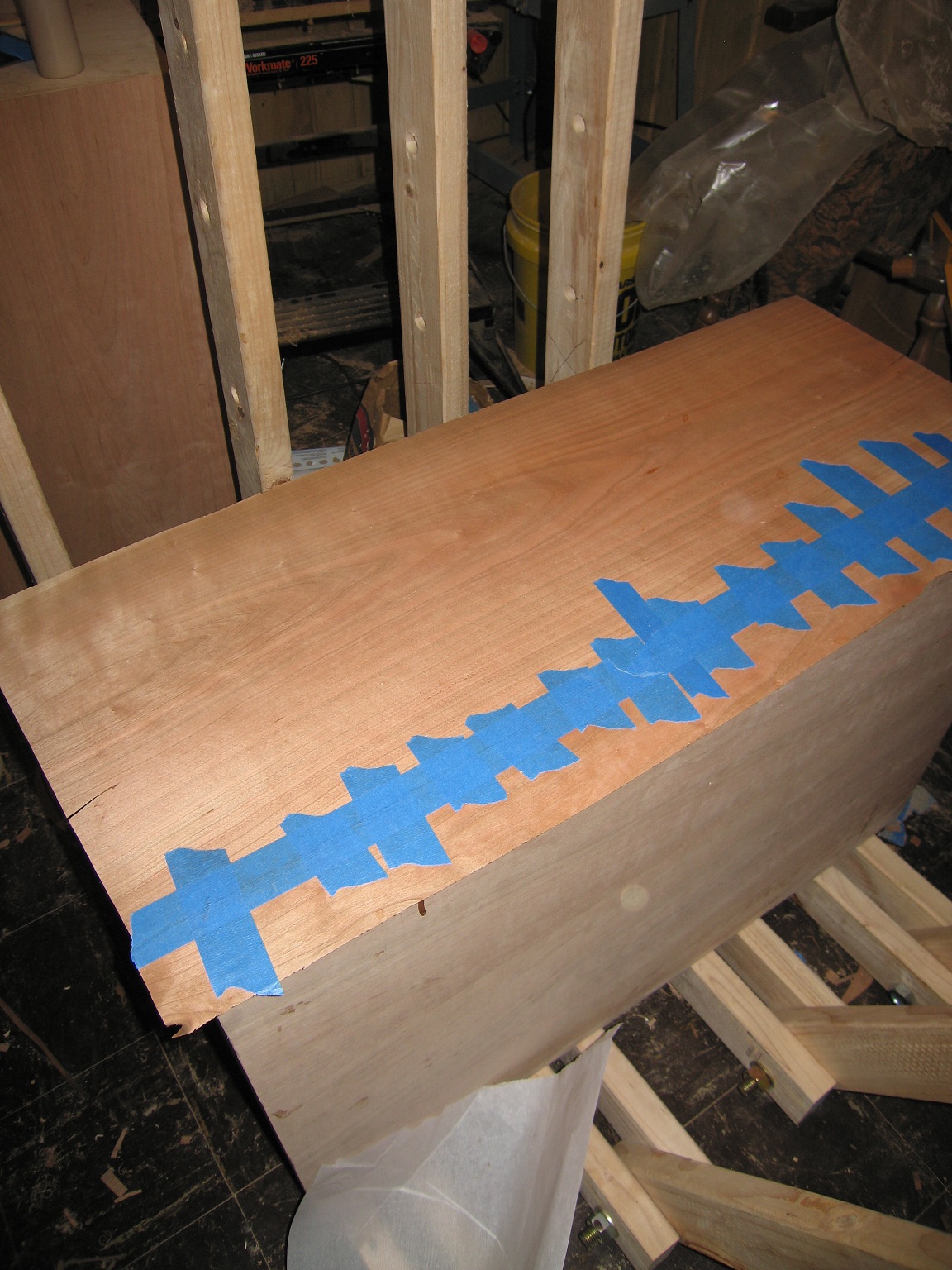

Router guide for horn:

Rear open encolsure:

I decided to use spliced leaves of veneer and made a what was probably a bad choice of contact cement to apply the veneer. Following the glue directions closer might have helped, but I had done some veneer work years ago and had decent results. I thought that I knew what I was doing. That wasn't the case. I started on the backs of the speakers, but the results were so bad that I stripped the veneer off and decided to start over. To replace the veneer, I purchased 2-ply veneer and it worked well. There was a lot more stiffness, structure, and durability than the veneer leaves that I was using. Looking back, changing the brand of contact cement may have worked with 2-ply veneer, but I decided to make a veneer press. Some of the veneer press images are shown below:

The press works fairly well. I am sure that it doesn't come neer the 100 psi recommended on the bottle, but vacuum presses can't exceed 14.7 psi, so I took the chance. In general the press worked well. In the future, I would expand my press clamps from 8 to 12. My first attempt to span about 3.5 ft with 2X4s. I used 4 press clamps on the first assembly. A 2X4 broke with force being applied by any of the clamps. I switched to 2X6 lumber on the top and increased the strength by a factor of about 2.5 times. I also used fewer clamps per assembly and shorted the span of each assembly to about 2 feet. This increased the press strength substantially. I was still never sure if anything would break but it worked well. For the platten that was used to press the veneer, I glued and nailed two sheets of plywood to make a stifff platten. For places where I rounded the corners of the cabinet with my sander, I had to go back and reclamp those area separately. I also ran into problems on the front of the speaker cabinets. The area between horn and the woofer were too flexible to generate a decent clamping force. If my internal braces were in place, it probably would have worked better. I definitely do not recommend that everyone switches from veneering to building a press. The press was expensive and still had areas where the veneer did not adheer properly. If people use a better contact cement and a more rigid veneer like 2-ply or NBL veneer, they should be fine. Also, I don't think that a veneer press would be a suitable choice for MDF due to strength and flexibility issues. Next time, I will probably take Bill Epstein's advice and try urea resin for glue.

|

|

|

|