|

|

|

|

|

|

| Re: My 4 Pi Build [message #97053 is a reply to message #96988] |

Tue, 10 October 2023 12:20   |

Unity_Coupled

Unity_Coupled

Messages: 20

Registered: September 2023

|

Chancellor |

|

|

Progress on the build has been pretty slow lately as I've had to prioritize farm and vineyard work, as well as audio repairs for customers. Just a few small updates for now...

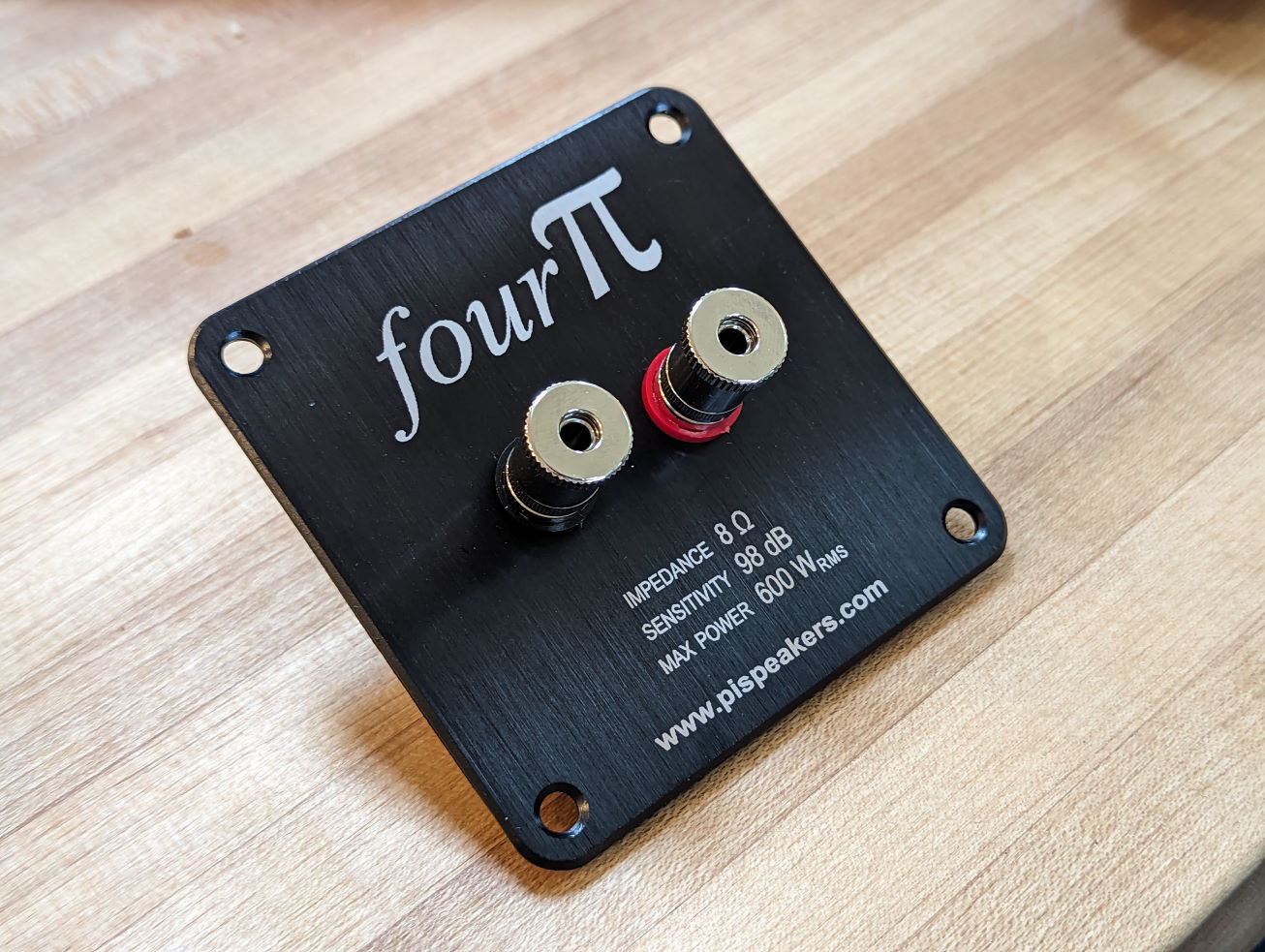

The terminal plates are back after getting laser engraved. I think they turned out nicely. I went with a slightly different design than what I posted above. If anyone wants to copy this, feel free to PM me for a vector file.

Yesterday I picked up a couple sheets of MDF along with Walnut veneer. I unrolled the veneer sheet and sandwiched it between the fiber boards so it would start to flatten out.

I purchased all the fasteners for the drivers from McMaster. For anyone interested, this is what I ordered:

Woofer

91251A550 Black-Oxide Socket Head Screw, 1/4"-20 x 2"

90975A307 Steel Tee Nut 1/4"-20

Waveguide

91255A278 Black-Oxide Button Head Hex Screw, 10-32 x 2"

90975A306 Steel Tee Nut 10-32

Crossover boards

94639A342 Nylon Spacer, 5/16" OD, 1/4" Long, for Number 8 Screw Size

That's all for now!

-

Attachment: plate_a.jpg

Attachment: plate_a.jpg

(Size: 233.68KB, Downloaded 1168 times)

-

Attachment: plate_b.jpg

Attachment: plate_b.jpg

(Size: 225.75KB, Downloaded 1172 times)

-

Attachment: ive_got_wood.jpg

Attachment: ive_got_wood.jpg

(Size: 125.09KB, Downloaded 1150 times)

-

Attachment: fasteners.jpg

Attachment: fasteners.jpg

(Size: 86.61KB, Downloaded 1178 times)

-

Attachment: wgscrew.jpg

Attachment: wgscrew.jpg

(Size: 97.69KB, Downloaded 1173 times)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Re: My 4 Pi Build [message #97073 is a reply to message #96988] |

Mon, 16 October 2023 13:15   |

Unity_Coupled

Unity_Coupled

Messages: 20

Registered: September 2023

|

Chancellor |

|

|

Potentially there's another issue, this one not so easy (or cheap) to resolve. I suspected from the get-go that at least one of my drivers was reconed, due to the over-application of glue around the dust cap on one of the cones, and the absence of a part number stamped on the backsides. Connecting a battery with the positive end to the red terminal draws the cone inward, so the polarity is correct. I built a jig for plotting impedance with REW and this is what I measured (average of four sweeps for ea. driver):

Compared to the JBL data, the impedance is not as smooth above 500hz, but it doesn't seem particularly bad either. As you've said in another post, the impedance notch at around 1k is a good indicator that the cone is aftermarket.

I have a single 2226H with an original cone and may decide to sell the 2226HPL's to purchase a second original H, but truthfully I prefer the HPL for the black outer ring. In any case, I'm going to wait until I can conduct final FR measurements and listening tests before making any decisions. I paid about $300 for both drivers, and if they're good enough I'm inclined to keep using them.

|

|

|

|