|

Home » Sponsored » Pi Speakers » Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center) (Building some Pi Speakers)

| Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center) [message #88442 is a reply to message #88057] |

Sun, 15 July 2018 17:19   |

joshua43214

joshua43214

Messages: 35

Registered: October 2016

Location: USA

|

Baron |

|

|

Once the glue dried, I used a router to flush trim the sides only. The front I sanded just enough to remove the glue, and the back I left untrimmed. The back takes a gasket, delaying trimming as long as possible delays any damage it might receive during construction.

I had saved all the offcuts from the horn to be used as internal bracing. I fitted one brace by trial and error using the bandsaw and a sanding block. Once the brace is close to being a good fit to the taper, one can hold the brace in place against one side, and scribe a line with a pencil laid flat on the other side. Then it is just a simple matter of trimming the edge parallel to the pencil line until it fits properly.

The fitted brace is then used as an angle guide for cutting the remaining braces, by taping the blanks to the fitted brace and running them past the blade.

Done wrong, this can be a very dangerous operation. Note the wide part of the guide is closer to the blade. If the tape fails and the part being cut slips, the taper will cause it to move away from the blade. If the taper is run the opposite way, the part will wedge between the blade and fence causing a kick back.

The braces are then trimmed to length. Note the stop block is making contact with the taper, not the end.

Each horn has a total of 6 braces, 4 for the longs sides, and 3 for the short sides.

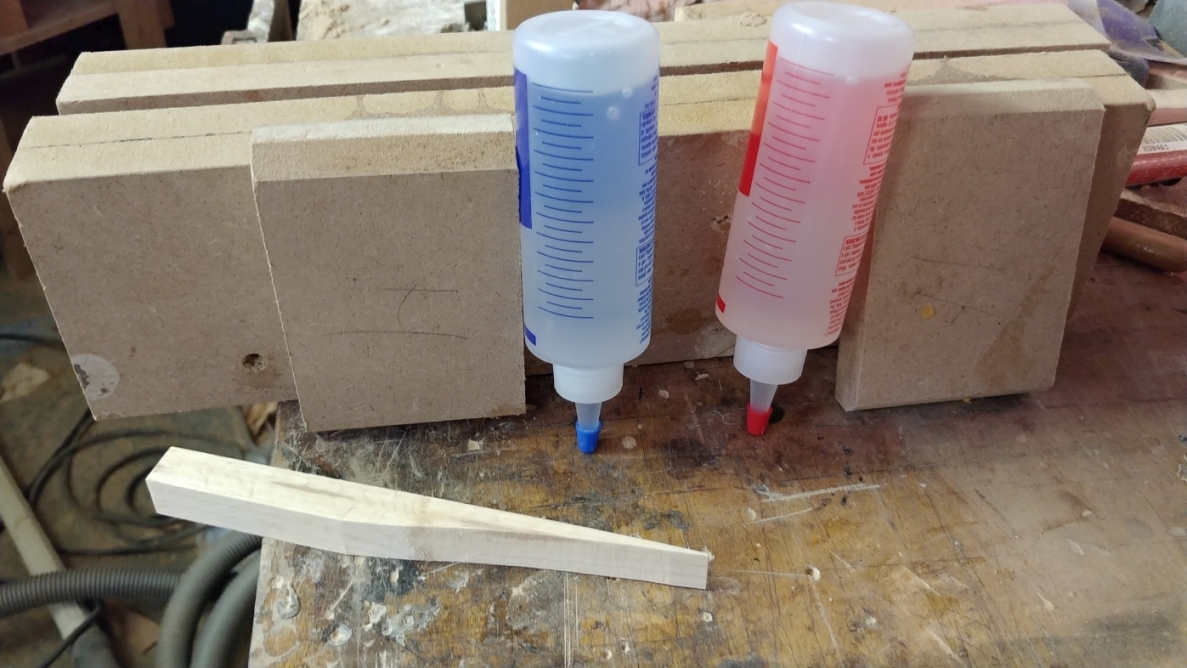

As uniform as these horns came out, they are not perfectly alike. Because of this, I chose to use 5 minute epoxy to glue the braces in. Un-adulterated epoxy is very hard and brittle, so not suited for this application because it might crack from the vibration of the driver. The stuff sold in hobby stores to the model airplane crowd is the right stuff, or the general purpose epoxy sold at the big box hardware stores. People often have trouble measuring epoxy, especially when it comes in tubes because the hardener and the resin have very different viscosities. Follow the directions, if it says equal volumes, do not use a scale. I invert the bottle for a few minutes, and use it in 2 line increments. I make a puddle of hardener (it is thicker) on some brown craft paper, then add the resin directly on top.

The reaction that epoxies undergo is exothermic, and generates heat. If you over mix it, all you are doing is adding energy to the reaction causing it to react even faster. Just mix it until it takes on a whitish color and use it. Once it starts to get stringy, stop even if it means you have to scrape it back off your parts. I had to mix 3 batches to get all the braces in.

I then cut out the fiberglass stuffing. Nothing fancy here, I just went at by eye with a utility knife. Took me all of 10 minutes.

The stuffing needs to go in before the driver mount. I also made sure the bracing would not interfere with the driver mounting screws. This is something that can be done in cad, but I just transferred the positions from the mount itself.

Up Next: Even more Horn building...

|

|

|

|

|

|

Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

|

|

Re: Build Thread: 2Pi Towers, 6Pi Corner horns (and possibly a sub and center)

|

Goto Forum:

Current Time: Thu Mar 05 11:45:14 CST 2026

|